Joshua Tree, Calif., is known for the stark desert beauty of its namesake national park and U.S. Marine Corps base at nearby 29 Palms. The town of 10,000 is a “craft beer desert,” with the nearest brewpub located over 50 miles away. Joshua Tree Brewery recognized the opportunity to serve the community and expand its popular beers from garage to a physical taproom but had to overcome challenges related to setting up an on-site wastewater treatment system to comply with state, county, and local discharge requirements. Working with Aquacycl, a wastewater technology startup, the brewery was able to demonstrate a cost-effective way to treat its wastewater to irrigation standards.

Opening a New Brewery

Despite not having a physical location, Joshua Tree Brewery was active in the community by donating beer to various fundraisers and hosting tastings at local events. The brewery won numerous awards for its beers and wanted to open a location where people could enjoy small-batch, craft beer made from local ingredients like white sage and cactus fruit.

Joshua Tree Brewery found the ideal location for its first taproom close to the entrance of the national park. In a region with no brewpubs, it seemed like a natural expansion for the six partners who wanted to open a physical location where they could sell their local craft beers to the community. Although the craft beer scene here had not developed as well as in nearby communities like San Diego, the cofounders believed there was ample demand.

As the partners started planning to open the taproom, they sat down with multiple departments within the county of San Bernardino. They quickly realized that environmental health was going to be the most challenging consideration as the wastewater effluent from the brewing process needed to be treated on-site to irrigation quality standards.

Breweries and food and beverage producers require large amounts of water during their production process. Joshua Tree Brewery was already minimizing water usage by using a three-vessel brewing process to draw out 75 to 80 percent of the sugars from grains. One gallon of beer produces approximately three gallons of wastewater, and the wastewater generated has organic carbon content that is up to 50 times more concentrated than what is measured in a typical sewer. The high concentration of organic carbon, measured as chemical oxygen demand (COD), can cause problems downstream and create toxicity events at local utilities. Most municipalities require slipstreaming (dilution) or charge high surcharges to handle it.

In Joshua Tree Brewery’s case, it wasn’t given either option. The town of Joshua Tree is on septic, and the proposed location sits above an aquifer that provides drinking water for the city of Joshua Tree. The county was concerned about any new contamination to the aquifer; any new business was subject to strict water quality standards for discharge. The water standards are monitored by the state, and San Bernardino County was particularly concerned about nitrogen discharge.

The requirements from the county are to reduce chemical or biological oxygen demand (COD/BOD) from 30,000 to less than 30 milligrams per liter (mg/L), total suspended solids (TSS) from 700 to less than 30 mg/L and total nitrogen from 100 to less than 10 mg/L. This is in accordance with California’s Title 22 requirement for discharging water for ground application.

When Joshua Tree Brewery started looking at options to treat wastewater, it quickly realized standard treatment systems were prohibitively expensive for a small company. As an independent brewer, wastewater treatment was something unfamiliar to the brewery partners, and the treatment requirements came close to shutting down the entire business. They investigated off-the-shelf anaerobic digesters, but there were limited options due to the small volume to treat. Conventional treatment systems are cost-effective for brewers that generate a large amount of wastewater; however, Joshua Tree Brewery was estimating generation of only 500 to 1,500 gallons per day (GPD).

The Solution

A wastewater consultant put Joshua Tree Brewery in contact with Aquacycl, a San Diego-based startup that uses microbial fuel cells to cost-effectively treat small volumes of very highly concentrated wastewater.

Aquacycl’s BioElectrochemical Treatment Technology (BETT) uses natural, locally sourced bacteria to accelerate wastewater treatment rates, eliminate primary sludge, minimize secondary sludge, and produce direct electricity. The wastewater and associated bacteria are fed to the BETT reactors and the bacteria form biofilms on the interior surfaces of each BETT reactor.

As the bacteria consume the organic matter in the wastewater, they release electrons as a part of their respiration process. In other words, these bacteria give away electrons when they breathe. As the microbes respire faster, they release more electrons, which are captured in the BETT reactor circuits and produce direct electrical current. The electrical current can be harvested by trickle-charging battery packs and the batteries can be used to power Aquacycl equipment, making BETT an energy-neutral system. Importantly, the more electrical current produced, the faster the bacteria breathe, which means they will eat faster and increase treatment rates. In short, more electricity production means a faster treatment rate.

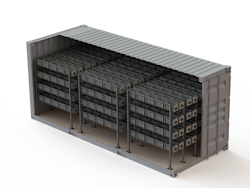

The system is modular, comprised of BETT reactors that are about the size of a standard car battery, all stacked together like Legos inside a 20-foot shipping container that sits outside of the brewery.

“Aquacycl’s system is great for the environment, but what has most impressed us is the user-friendliness of the system, the customer service, and the affordability,” said Dario Guerra, CEO and master brewer at Joshua Tree Brewery.

Compared to a conventional treatment system, Aquacycl’s packaged treatment plant was about half the price and occupied a smaller footprint. The system is offered on a service model, which reduced the upfront investment required for Joshua Tree Brewery. It is remotely monitored and controlled, allowing Joshua Tree Brewery to focus on brewing beer without needing to hire a wastewater treatment operator. The Aquacycl BETT User Interface allows both Joshua Tree Brewery and Aquacycl to see the performance of each individual BETT reactor and observe the operational performance of the system as a whole, providing real-time information to regulators, operators, and brewers. The treatment system requires maintenance once per year, which is performed as part of the Aquacycl service contract.

Using funds awarded from the Innovative Conservation Program (ICP), a grant program from the Metropolitan Water District of Southern California, the U.S. Bureau of Reclamation, and several other southwestern water agencies, Joshua Tree Brewery and Aquacycl installed a pilot system that demonstrated removal rates to the county and local water agencies. While the brewing partners were finalizing the brewery build-out, they would bring the wastewater that was generated from brewing in their garage and cycle it through the Aquacycl demonstration unit. The system was set up to treat 150 GPD of raw brewery wastewater (with no pretreatment) under batch and continuous operational conditions.

The BETT system scaled to remove up to 99 percent of COD, TSS, total sulfur, and about a third of total nitrogen, but it required a polishing step and denitrification to further reduce COD and nitrogen. Aquacycl worked with BioLargo, a publicly traded water technology company that provided technology to address the polishing steps.

Results

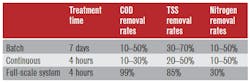

The demonstration unit was significantly smaller than the full-scale system needed for Joshua Tree Brewery. Even with the smaller size and lack of consistent wastewater volume, the system was able to prove removal rates that allowed regulators to provisionally sign off on the wastewater quality and allow Joshua Tree Brewery to continue development (see Table 1). The county’s approval is contingent on testing influent and effluent rates during full-scale operations when the brewery is operational.

The full-scale treatment system is designed to remove 99 percent of COD, from 30,000 mg/L to 300 mg/L. The polishing technology will remove the remaining COD down to 30 mg/L and nitrogen (from 50 mg/L to 10 mg/L). The fully integrated treatment system will treat 500 to 1,500 GPD.

Next Steps

Joshua Tree Brewery is in the final stages of planning and development to open, and the partners can see a light at the end of the tunnel. Having gone through the extensive process of dealing with on-site wastewater treatment, they want to showcase their system as part of the brewery experience. Customers visiting the Joshua Tree area are environmentally conscious, and the partners want to highlight that they are recovering water and reducing the impact of the beer. The water treated by the system will be discharged to leach pits, with possible future usage for landscape irrigation.

Eventually, the brewers plan to expand to a co-op, allowing other local brewers to showcase their beers without the same level of investment that Joshua Tree Brewery faced. This will allow small homebrewers the chance to try their recipes on larger scale equipment and bring new beers to the community.