Taking advantage of low pressure membranes in commercial systems

Low pressure elements are usually referred to as LP for low pressure or LE for low energy, as pressure and energy are interrelated the nomenclature used is interchangeable. Typically, the trade off with reverse osmosis membranes is between flow and rejection. For higher rejection, the membrane must be tightened to create lower flow. Conversely, higher flow requires a loosening of the membrane, resulting in higher salt passage. Thus, the two main reverse osmosis (RO) performance metrics move inversely with one another. In many commercial and industrial applications, however, maximizing permeate quality is not always necessary. In these instances LP/LE elements may be an excellent choice for many OEMs and end users.

There are a couple of advantages that can be achieved by using LP/LE membranes as an alternative to higher pressure standard RO elements in commercial RO systems. The advantage achieved will depend on how elements operate in a system. One option would be to run them at lower pressure to achieve energy savings. The second option is to operate them at the same pressure to increase permeate flow. In either case, the choice made can significantly influence pump selection, energy costs, permeate production and RO element life.

Option one: Save money

Using a low pressure membrane to reduce feed pressure requirements can save money by lowering initial capital equipment costs. This is done primarily by enabling the use of a less expensive, lower pressure pump. Lower pressure can also mean reduced operating costs since less energy is required to force water through the membrane barrier layer. Examples one and two demonstrate using an RO system design program to evaluate the differences between a standard RO element and a LP/LE element.

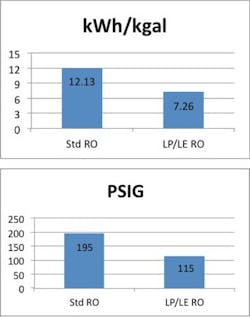

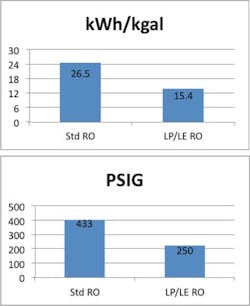

Example one – Low TDS (500 PPM)

In this comparison an RO system using a single 4040 element is used to produce a permeate flow rate of 2,900 gallons per day (GPD) at a water temperature of 25⁰ C. In the bar charts below, the standard RO element required 12.13 kilowatt hours to produce 1,000 gallons of permeate. The LP/LE required only 7.26 kilowatt hours to make the same amount of water. In terms of applied pressure, the standard RO operated at 195 psig, while the LP/LE element operated at 115 psig.

In this case, the LP/LE element used 41 percent less energy/pressure than the standard RO membrane. This notable difference can often help system builders to use a smaller, less expensive pump. It also can lower operating expenses through lower electrical bills.

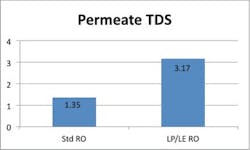

However, there is a trade off to be made with LP/LE membranes and it comes in terms of lower permeate quality. The LP/LE membrane in this example had 235 percent higher salt passage. In practical terms, however, it means little when operating on a low TDS feed water. In this case the TDS of the standard RO was 1.35 ppm, whereas the TDS of the LP/LE was 3.17. Normally, this would not be considered significant enough to make much of a difference in most commercial applications.

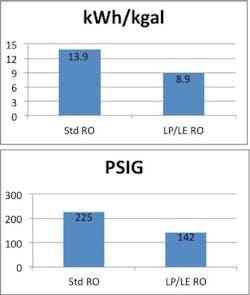

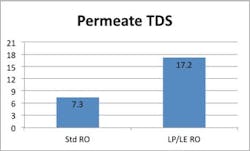

Example two – High TDS (2,000 PPM)

Example two shows the same RO system using a single 4040 element at the same operating conditions but with a feed water TDS of 2,000 ppm. In this situation, the standard RO element required 13.9 kilowatt hours to produce 1,000 gallons of permeate. The LP/LE required only 8.9 kilowatt hours to make the same amount of water. In terms of applied pressure, the standard RO operated at 225 psig, while LP/LE element operated at 142 psig.

The best way to determine if an LP/LE element will be suitable for a particular application is to model it in the respective element manufacturer’s design program.

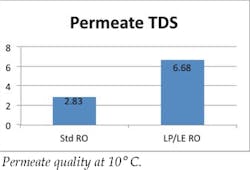

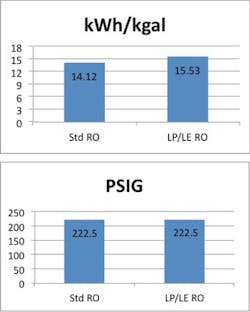

Cold water membrane

Another way to use low pressure membranes is to achieve higher permeate flows on low temperature feed water. That is why they are sometimes referred to as “cold water membranes.” The charts below show what would happen if the feed water temperature was changed from 25⁰ C to 10⁰ C using 500 ppm TDS feed water.

Continuing with another example, operating an RO system on cold feed water can have a dramatic impact on energy and feed pressure. Using LP/LE membranes can help offset this effect and facilitate continued high volumes of permeate water at reasonable feed pump pressures without notably compromising permeate quality.

Option two: Make more water

The second option for running LP/LE elements is to run them at standard RO operating pressures to increase permeate flow in an existing system. Element manufacturers would normally not recommend doing this, however, it could result in excessive flux rates. Operating elements at too high a flux can shorten element life by accelerating the onset of element scaling and/or fouling.

Often, membranes used in this manner are installed as replacement elements in existing systems where the owner needs more water production but would like to avoid the cost of purchasing and installing an entirely new RO system. The end result is similar to the example given earlier for a system operated on cold water. Here an LP/LE membrane may be able to supply the extra water needed without requiring switching to a higher pressure pump and/or adding more elements.

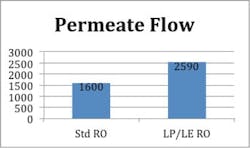

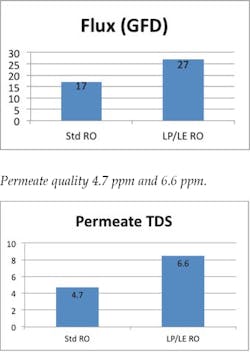

In this example we can see what happens to flux rates when a standard element is replaced with an LP/LE membrane on a system initially set up to run at 17 gallons per square foot per day (GFD) at 10⁰ C and 2,000 ppm feed water. Note that the feed pressure is kept constant.

By replacing a standard RO membrane with an LP/LE element, permeate flow increases from 1,600 GPD to 2,550 GPD, and the operating flux would also increase from 17 GFD to 27 GFD. The LP/LE element can offer substantially more water but at the tradeoff of higher flux and the likelihood of shorter element life.

LP/LE elements can be used to either save on capital and operating expenses or to increase water output by operating them at higher flux rates. Understanding the tradeoffs in terms of permeate quality and element life can help operators determine how best to use them in various commercial applications.

Bill Loyd is a technical service specialist for residential and commercial RO elements at Dow Water and Process Solutions in Edina, Minn. He can be reached at 952-897-4286 for questions or comments on this article.

Note: All comparisons modeled in Dow’s ROSA program using DOW FILMTEC LCHR and LCLE 4040 elements.