Today, you cannot read a magazine without encountering at least one article about the "Internet of Everything," "Internet of Things" or "the cloud." But what do these mean? How can this phenomenon benefit people who primarily think of the cloud as being one part of the water cycle? Are these terms just fashionable buzzwords, or do they speak to some real value that we can harness to improve operations? What are some concrete ways that those of us who look after our water supply can put these new concepts to work for us? This article attempts to answer those questions.

Focusing on core objectives

Accomplishing the jobs in the water industry seems to get more difficult. The issues facing the industry are well established and include:

- Retiring personnel reducing the workforce and taking important knowledge with them

- Reduced funding

- Increasing regulations

- Drought

- Strategies (such as reuse) to overcome water scarcity

With potentially fewer people to complete more complex work, looking to new technologies and service-delivery models to accomplish peripheral tasks makes sense. With this technology, water treatment professionals can focus on the main task. This type application is when the Internet of Things (IoT) makes sense.

IoT is new technology and a new service-delivery model that makes in-the-field devices smart and allows them to provide near real-time information to end users anywhere, as long as they have an Internet connection. It is a way to avoid heavy investments in communication infrastructure and specialized software by relying on third-party providers to make end users’ information available anywhere at any time. It allows water treatment professionals to focus on keeping the water clean, while trusting technology to deliver the data required to accomplish their clean-water mission.

Sample scenario

Chlorine residual at the end of a distribution system must remain above a certain level to meet regulations and ensure public health. The end of the distribution system is miles away from the treatment plant, with hills, thick forest and tall buildings in between. Three solutions, detailed in this section, could be implemented to measure and monitor this safety-critical parameter.

Manual approach

The superintendent sends one of the municipality’s representatives to the distant end of the distribution system once per day to manually check chlorine residual level. The test takes 5 minutes. The round trip takes 60 minutes. With this solution, nearly 5 ½ hours of the staff’s limited time each week is allocated to verifying the chlorine residual level. From a materials cost perspective, the testing kit is inexpensive. The wear and tear on and the fuel for a vehicle are appreciable ongoing costs. The most significant cost is the opportunity cost of losing the staff member’s availability to complete more valuable tasks for 5 ½ hours per week.

Graphic courtesy of Phoenix Contact

Traditional SCADA approach

The superintendent invests in a traditional supervisory control and data acquisition (SCADA) system to automatically measure and report the chlorine residual level to the treatment plant’s staff in the control room. This level data can be sent as an input to the process controller to automatically turn on dosing equipment to offset any drop in chlorine residual level. The SCADA system saves 5 ½ hours per week in staff time. It also eliminates the cost of the vehicle used for traveling to check chlorine residual level.

Fairly large capital costs would be incurred because installing a remote terminal unit (RTU) may cost up to $10,000. Also, an engineering study would likely need to be conducted to determine the locations at which to install the radio repeaters to receive the signal from the RTU and send it to the control room. If a dedicated radio tower must be erected to enable signal transmission, the overall infrastructure costs could be in the tens of thousands of dollars. At the treatment plant, a server with dedicated SCADA software would need to be purchased, and a system integrator would likely need to be hired to develop custom software system overview screens. Ongoing costs would consist of patching, maintenance and upgrade management on the server and software.

An IoT approach

As in the traditional SCADA approach, taking advantage of the IoT frees up staff time when compared to the manual chlorine residual testing method. However, instead of spending nearly $10,000 on a traditional programmable logic controller (PLC) based RTU, tens of thousands for radio and repeater infrastructure, and many thousands more on a dedicated server and SCADA software, the IoT approach requires different setup processes.

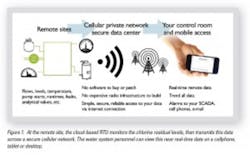

First, the end user, (or an installing system integrator working on the end user’s behalf) would purchase the cloud-based RTU (at less than half the cost of a traditional PLC-based RTU, installed). Next, the customer would contact the cloud-based remote monitoring service provider to activate the RTU. Within a day from the project’s start, the end user will begin to see the chlorine residual value on a cellphone, tablet or Internet-connected desktop.

An ongoing monthly cost paid to the cloud-based remote monitoring service provider would cover the cost of the cellular data plan that conveys the data from the RTU to the cellular tower, as well as the cost for accessing the provider’s password-protected Web portal, on which the end user can view the information. Alarms, trends, reports, historical and near real-time data can all be accessed with this system. Figure 1 illustrates how this works.

IoT candidate applications

Which applications are likely to benefit from the IoT approach? The water industry has reliably deployed traditional SCADA systems for decades. In many instances, this traditional system architecture and service delivery model is still the most appropriate way to monitor the water distribution system and remote sites.

The IoT should be embraced in these three application types:

- Small water systems. Historically, the substantial, fixed capital costs associated with a SCADA system have been too high a hurdle for small system operators to pay. With no capital costs related to software, servers or radio infrastructure, a cloud-based, remote monitoring approach lowers the capital cost bar.

- Difficult-to-reach, remote sites of large water systems. Many end users responsible for large systems actively use a traditional SCADA system and enjoy the benefits that SCADA provides. However, the system may have one or two sites that have proven too challenging to connect to the network because of topography, foliage or some other barrier to effective radio frequency transmission. As long as the remote site has connectivity to a cellular tower, an IoT system can connect these orphaned, remote sites’ data to the end user’s personnel or onto the same PCs that run the existing on-site SCADA system.

- Mobile or temporary monitoring. Sometimes temporarily monitoring flow, pressure or some analytical value to assist in system planning or to satisfy regulatory requirements is beneficial. The IoT makes this easy. An RTU’s cellular modem simply connects to the nearest cellular tower and transmits the data to the cloud-based server, from which it is available for the end user to view from anywhere.

Conclusion

The IoT is not just the latest buzzword. It describes a valuable new way to acquire data effectively and inexpensively. This technology ultimately enables water professionals to focus on their core missions and enhance water system operations.

Dave Eifert is the industry manager, Water Resources, for Phoenix Contact USA, Middletown, Pennsylvania. An active member of the American Water Works Association, the Water Environment Federation and the International Society of Automation, Eifert has focused on automation and controls, energy management, and networking and security during his 27-year professional career. He may be reached at [email protected].