Oil-water separator

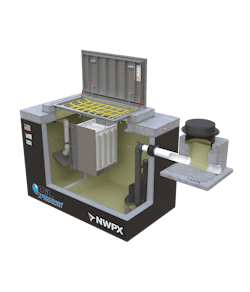

NWPX Park, a division of NWPX Infrastructure, is a global leader in the design and construction of innovative water utilities and environmental solutions, and is proud to highlight its OilTrooper Oil-Water Separator, a cutting-edge system engineered for advanced contaminant removal in wastewater treatment. Leveraging NWPX’s patented Coalescing Media Pack (CMP) and a multi-compartment basin, the OilTrooper efficiently separates sediment, hydrocarbons, and oil from water, ensuring reliable performance and environmental compliance across commercial and industrial applications. The pre-engineered oil-water separator system is delivered with all internal components fully assembled, making installation quick, easy, and efficient.

OilTrooper delivers robust protection of water resources and optimal reliability for commercial applications and industrial environments. Its standout CMP efficiently isolates even the finest solids and smallest oil droplets, maximizing contaminant removal and helping businesses meet regulatory demands while safeguarding water quality. Multi-chambered baffles guide wastewater through the unit, ensuring heavy sand settles while hydrocarbons rise to the surface, so only clean, compliant water exits the system.

Automatic, tank-mounted sensors continuously monitor separator capacity, ending the need for manual checks and minimizing maintenance overhead. When capacity is reached, a remote alarm alerts operators. Built-in spill control features, such as the oil stop valve and oil dam, deliver additional layers of environmental protection, making operation both safe and efficient.

The OilTrooper system adapts easily to different site conditions with models available in high-strength precast concrete, steel, or fiberglass, and capacities ranging from 100 to 20,000 gallons. Installations can be above or below grade, and units are offered in both pedestrian and traffic-rated versions. A UL certified exterior NEMA 4X control panel and internal sensors provide real-time status updates and high oil level alerts, optimizing incident response and spill prevention.

Certified to comply with Uniform Plumbing Code (UPC) standards, OilTrooper® is made in America and engineered for low maintenance performance, reducing costs and downtime for end users.

The OilTrooper Oil-Water Separator empowers facilities to confidently meet stringent regulatory standards while protecting local water resources, reducing operational risk, and supporting long-term sustainability. By combining advanced contaminant removal with automated monitoring and versatile installation options, OilTrooper positions organizations for ongoing compliance, increased efficiency, and strong environmental stewardship in every application.

About NWPX

Founded in 1966, NWPX is a leading manufacturer of water-related infrastructure products. In addition to being the largest manufacturer of engineered water transmission systems in North America, the company also provides solution-based products for a wide range of markets including high-quality reinforced precast concrete products and lined precast sanitary sewer system components, which are manufactured under the NWPX Geneva brand, as well as water distribution and management equipment including pump lift stations, wastewater pretreatment, and stormwater quality products through the NWPX Park brand. NWPX Park offers custom solutions, including pump lift stations, meter vaults, oil-water separators, grease interceptors, vault systems, and automated controls designed for seamless installation and reliable operation.

For more information on leading solutions, please visit www.nwpx.com.