by Tim Jordan

• Tubular membranes from Koch Membrane Systems handle extremely difficult oil and glycol mix in wastewater at Metaldyne plant in Ohio.

Finding the most effective, reliable and economical method for separating and concentrating die lubricant is no easy task for die casting plants – and the situation at the Metaldyne aluminum die casting plant in Twinsburg, OH, was no different.

For over a decade, Bill Cleary, the wastewater treatment manager, worked with 22 different wastewater treatment vendors, in addition to experts from academia and the U.S. Department of Energy to find the optimal solution for his plant.

The Twinsburg plant – a facility of the Plymouth, MI-based manufacturer of metal-based components, assemblies, and modules for chassis, engine, driveline, and transmission applications – is a world leader in the production of aluminum valve body castings. To facilitate this process, Metaldyne has developed a world class die casting process that utilizes a specially-formulated die lubricant, an oil-and-water emulsion that helps control the temperature of the die as well as removal of the complex castings during the part ejection process.

Each cycle of the highly-automated process begins with numerous nozzles spraying a controlled volume of lubricant onto specific locations on the die. Next, molten aluminum, at 1,250°F, is auto-ladled into the cold chamber and injected into the die under high pressure.

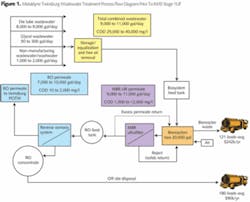

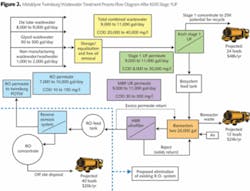

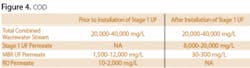

The plant's drainage system collects the waste generated from the casting process, including the die lubricant, as well as detergents from washing operations and glycol from the hydraulic fluid used in the robotic machinery. In addition, some process cooling water and cooling tower bleed are piped into the wastewater treatment system. The total combined wastewater flow is 9,000-11,000 gallons per day (gpd), with chemical oxygen demand (COD) ranging of 20,000-40,000 mg/L.

Clogging, High Disposal Costs

The oil from the die lube and the glycol from the hydraulic fluid combine to create an extremely difficult wastewater treatment challenge, explains Bill Cleary. We cannot use flammable hydraulic oil because of the high temperatures of the molten metal. Instead, we use glycol which, must be removed to meet our COD discharge limits.

The plant's original physical-chemical wastewater treatment system performed poorly, because it was difficult to maintain a consistent recipe. This situation was further complicated by the uncontrolled and unpredictable flow rate and the difficult composition of the wastewater stream.

In 1995, the plant installed a bioreactor system to consume the glycol. The membrane bioreactor (MBR) system was arranged with the tubular membranes external from the bioreactor, thus separating the water from the activated sludge. The effluent from the MBR was polished by a reverse osmosis (RO) system, prior to discharge into the municipal wastewater system (see Figure 1).

Unfortunately, the tubular membranes in the MBR had difficulty handling the oils and greases, resulting in clogged pores in as little as three weeks. A scum, with a consistency of a foamy milkshake, formed on the top of the bioreactor tanks, often overflowing onto the floor. The die lube, which accounted for approximately 80% of the waste stream, seemed to be the source of the problem.

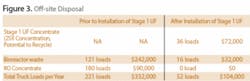

Uncontrolled wasting from the biological tank caused a mess and it became extremely expensive to haul away all of the waste, said Cleary. We were hauling over 120 truckloads of bioreactor waste each year, at an annual cost of nearly a quarter of a million dollars. We knew that we needed to find an effective way to prefilter the feed water to the MBR in order to remove the oil and other components that were wreaking havoc on the MBR system.

New Tubular Membranes

Cleary and his team worked with almost two dozen vendors to test a variety of pretreatment solutions, utilizing many different types of membranes. For example, a grant from the U.S. Department of Energy funded the testing of a spinning membrane system. The system worked effectively, but it wasn't commercially available and high electricity costs made the system uneconomical.

A few years ago, we heard that a new tubular membrane was developed by Koch Membrane Systems that could handle extremely difficult oily wastewater, and indeed it proved effective, says Cleary. Finally, we had a system capable of removing the solids upstream of our bioreactor.

In 2006, the Twinsburg plant installed a Konsolidator™ 150 Industrial Wastewater System from Koch Membrane Systems Inc. (KMS) of Wilmington, MA. The pre-engineered, pre-packaged system contains 150 FEG™ PLUS tubular UF membranes.

These tubular membranes have an open channel configuration capable of handling extremely high suspended solids loads. They're well suited to applications in heavy industrial wastes including oily wastewaters and can be cleaned mechanically using spongeballs. The membranes are rated at 120,000 Dalton molecular weight cutoff (MWCO), roughly equivalent to a membrane pore size of 0.02 microns (see Figure 2).

A Process that Works

This new Stage 1 UF system removes solids and concentrates the waste 25 times, equivalent to a 96% reduction in water content. Cleary is investigating options for recycling the oily concentrate.

Removal of the solids enables the bioreactor process to work smoothly. Off-site disposal of bioreactor waste has been reduced tenfold, from an average of 10 truckloads per month – at a cost of $242,000/year, to only one and a half truckload per month – at a cost of $32,000/year (see Figure 3).

Prior to the installation of the Stage 1 UF system, the MBR permeate contained a wide variation in COD levels, ranging from 1,500 to 12,000 mg/L. With the Stage 1 UF system, the MBR system now produces permeate with COD of only 30 to 300 mg/L (see Figure 4). The MBR permeate now is well below the discharge standards set for the municipal wastewater system (COD <500 mg/L) even without polishing with RO. As a result, the RO system was shut down and permeate from the MBR is discharged directly to the sewer.

Conclusion

Cleary calculates that the total annual cost of off-site disposal of waste has been reduced from $332,000 to $104,000, a 69% reduction amounting to a savings of $228,000 a year.

We have been able to reduce our costs and still maintain a reliable, manageable process, says Cleary. We went five months without wasting in the bio system and without any ill effects. With the Stage 1 UF system, we finally have a process that works.

About the Author: Tim Jordan is a Midwest regional sales manager with Koch Membrane Systems Inc. and has 17 years of experience with membrane applications. With over 15,000 membrane systems installed globally, KMS serves food processing, life sciences, and general manufacturing industries, and provides potable water and wastewater treatment for communities of all sizes. Contact: +1-888-677-5624, [email protected] or www.kochmembrane.com