Survey Examines Wastewater Treatment Costs

Annual wastewater treatment costs are expected to rise at a moderate pace over the next five years, with price increases projected to remain under 5% for the period, according to a majority of those responding to a recent survey of subscribers to Industrial WaterWorld Magazine.

In November 2010, Industrial WaterWorld emailed a benchmarking survey to 11,000+ subscribers. The survey was developed by a group of MBA students at the University of Michigan - Ross School of Business as part of their Marketing Research Design and Analysis course. The student team asked Algal Scientific Corp. for support by providing a relevant research topic and assisting in crafting survey questions.

Algal Scientific is developing algae-based advanced wastewater treatment systems. Recent Michigan MBA graduates who had worked in the water industry, along with two PhD candidates doing research on algae in biology and chemical engineering, founded Algal Scientific and won the 2009 DTE Clean Energy Prize. Algal Scientific offered to support the student research with the goal of establishing benchmarks for the wastewater industry and in particular seeking to identify the costs of various treatment options for the removal of BOD, nitrogen and phosphorus.

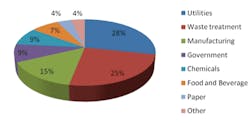

There were over 175 respondents to the survey from a variety of industries. While this is by no means representative of the entire wastewater treatment industry, the diverse mix of respondents provided useful information about treatment needs and costs across multiple industries. The largest percentage of respondents were from utilities, while representatives of manufacturing, government, chemicals, and food and beverage were the next largest groups with 7-15% of total responses each.

In addition to a diversity of industries represented, respondents represented facilities with a wide variety of daily wastewater flow rates, ranging from <100,000 gallons per day (gpd) to >10 million gpd. The proportion of respondents with each given flow rate range was nearly equal, demonstrating that facilities range in size irrespective of industry.

Figure 1. Percentage of total respondents (n=176) by industry

Not surprisingly, costs associated with treatment declined as facility size increased. For facilities with flows less than 100,000 gpd, the treatment cost per 1000 gallons was nearly 15 times greater than that incurred by the largest facilities. This may indicate a market pain for new, low-cost solutions, especially at small facilities where treatment costs are a larger fraction of overall operations.

Among the 90 respondents who described how they managed their wastewater, about 55% managed their own on-site treatment system, 12% discharged to the sewer and paid surcharges, and 4% outsourced the operation of their on-site treatment system. Of those who managed their own treatment system, about 25% also operated under a NPDES permit and discharged directly to a waterway.

In terms of technology, there was considerable variation among respondents who used on-site treatment systems. Bacteria-based activated sludge systems comprised about half of surveyed systems. In addition, about 15-25% of respondents also indicated they used anaerobic digestion, additional nutrient treatment (such as denitrification or phosphorous flocculation), or some other packaged system. Roughly 40% of respondents indicated they used more than one treatment technology, with the most common combination being activated sludge with additional nutrient treatment.

Since the initial target markets that Algal Scientific is addressing are the food, beverage, chemicals and other manufacturing industries that currently pay surcharges to their local wastewater treatment plant due to the strength of their wastewater, these sectors were analyzed more closely. About 35% of the respondents in these sectors indicated they paid surcharges. Of those that paid surcharges, 45% also had on-site treatment systems.

Among the surcharge payers that provided an estimate, the average annual spending was nearly $600,000 based on an average daily flow of about 760,000 gallons, with an average spending of $2.06 (ranging from $1.23 to $3.42) per 1000 gallons of water discharged. Based on a small sample, the surcharges were about $0.21/lb each for both BOD and TSS, and $0.96/lb for NH4-N. Furthermore, among respondents with an opinion, 24% thought that their spending would decrease or stay the same over the next 5 years while 44% expected annual increases of more than 5%. Another 19% expected increases to average more than 10% per year.

Among those organizations paying surcharges, on average they expected 5-10% annual increases in their costs, and all that gave an opinion said they would be moderately or very interested in a new on-site system if it could reduce their costs by 40% on average.

In contrast, for those who don't pay surcharges, only half would be more than slightly interested in a new system even if it could save them over 40%. This group also expected their costs to rise at a lower rate than those paying surcharges. One possible conclusion is that organizations that do not pay surcharges believe they can control their costs better than those who do. Nevertheless, this suggests that a sizeable portion of facilities producing high strength wastewater are experiencing significant treatment costs and expect these to increase.

Past IWW Issues