Cooling Water Control and Online Corrosion Monitoring

by Jack Lehner

Process and pipeline corrosion is a major problem in the petroleum, chemical and process industries. This is true also of cooling water systems in these facilities. Changes are constantly occurring within any process system that need to be controlled.

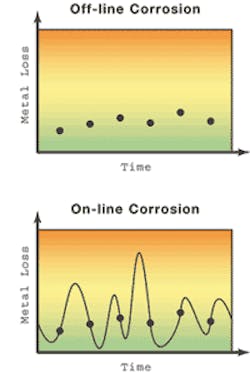

In cooling water, this control is usually applied with addition of inhibitors. The problem is this control is usually based on a pH of the system, an analysis of a coupon in the system, or a grab sample taken by a water treatment service team. Additions of inhibitor to the system are then made based on data generated from one of the above tests. But conditions within the cooling system are constantly changing and need constant monitoring to assure the proper additive rates are being used.

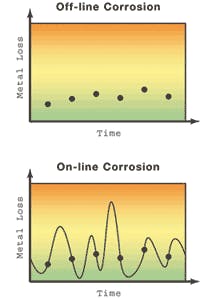

Process changes or process leaks can affect corrosiveness of the circulating water; if these changes are known then additives can be metered into the process to maintain a stable consistent corrosion rate. By utilizing this technique one can optimize effectiveness of the inhibitor package, minimize the corrosive effect, increase on-stream time, minimize maintenance costs, and significantly reduce the potential for lost product and environmental damage. The difficulty up to this point has been the ability to see these physical changes in real time so that process changes, or preplanned maintenance, can be effective.

There are currently several traditional methods of corrosion monitoring being used. Metal coupons are prepared, pre-weighed and inserted into the pipe where they’re left in contact with the material flowing through the line for a period of three to four months. They’re then removed from the pipe, cleaned and reweighed to determine the metal loss. Although this is an effective method for determining corrosion within a given system, it’s, at best, historical data and an average corrosion rate over the time of the test.

General and pitting corrosion can be seen on the coupons, but pitting severity within the pipe is left unknown. Linear polarization resistance (LPR) corrosion probes are also available for use in systems such as these, but they only measure general corrosion and, in most cases, don’t provide real-time monitoring. Historical data is good, but not when one is trying to control the fluctuations of a process. Adding inhibitors based on past data can be an extra expense; due to fluctuations, they may be overfed at some periods and under fed at others. It has been shown that both can cause serious damage to process systems.

The alternative to this problem is real-time corrosion monitoring. Pepperl+Fuchs Inc. has developed an automated on-line in real-time corrosion monitor that’s installed in-line through a variety of convenient connection methods. Known as CorrTran® MV, this technology measures both general corrosion and localized (pitting) corrosion in liquid or gaseous systems.

General corrosion occurs at nearly the same rate across the surface of the material that’s exposed to the corrosive atmosphere. Localized corrosion is commonly known as pitting corrosion. These “pits” are found on the surface of the metal and aren’t uniform across the surface. Seventy to 90% of equipment and pipeline failures are attributed to pitting corrosion and very few of the corrosion monitoring equipment are able to show this effect with such ease.

This real-time corrosion monitoring technology uses LPR, HDA and ECN measurements in its processing algorithms. LPR involves the measurement of polarization resistance of the corroding electrode to determine the corrosion current. Since the voltage-current response of the corroding elements tends to be linear over a small range, determining polarization resistance allows the corrosion current to be determined. The slope of the response, polarization resistance, is inversely proportional to the corrosion current, so a corrosion rate can be calculated.

HDA is harmonic distortion analysis, which measures resistance of the corrosive solution by applying a low frequency sine wave to the measurement current. Using harmonic analysis, the solution resistance is determined and combined with the polarization resistance of the LPR method to calculate a more accurate general corrosion rate. The electrochemical Stern-Geary Beta-value is determined and updated automatically after each cycle for accurate results. This allows the system to monitor changing conditions within the fluid being processed.

ECN is electrochemical noise. This method evaluates the fluctuation in current and voltage noise generated at the corroding metal – solution interface. The technique is generally used to detect non-uniform or localized (pitting) corrosion.

This technology utilizes all three of these monitoring techniques to provide a corrosion rate most comparable to the coupon method. They’re the first field-mounted devices to use the strength of each of these corrosion measuring techniques to provide a corrosion rate in a 4-20 mA process signal that’s multivariable. The technology also allows conductivity measurement to be made available as an additional output.

With proper mechanical connections, CorrTran MV delivers a standard, loop powered, 2-wire, 4-20 mA output with a multivariable HART signal. The general or localized corrosion can be set as the primary or secondary HART variable, and the conductivity value set as the third variable. This data can be transmitted to the distributed control system (DCS) system and the trend graphs compared to other variables as they occur. Also, a control scheme can be set up to meter in inhibitors to maintain a given corrosion rate.

With this new on-line data, process operators can monitor corrosion rates within their existing software and control system like any other process variable such as pressure, temperature, flow and pH. If corrosion occurs, the effect of process condition changes or additive concentration can be relayed and changes made to reduce it. Process operators can now monitor the effects of additives on the corrosive effect of the pipeline or vessel as changes are being made, and maintenance personnel can now preplan when lines or equipment needs service based on analysis of the systems corrosive affect.

About the Author: Jack Lehner is business development manager for Twinsburg, OH-based Pepperl+Fuchs Inc. Contact: 330-486-0002 or [email protected]