Treating FGD Wastewater: Phase 2 Clean Air Act Amendments Make It Hot Topic

by Brian Heimbigner

Flue gas desulfurization is a hot topic right now with new emissions standards from Phase 2 of the Clean Air Act amendments coming into effect. The standards call for further reduction of sulfur dioxide (SO2) emissions from coal-burning power plants. Earlier reductions were required about 15 years ago by Phase 1 of the Act. FGD systems use limestone-forced-oxidation (LSFO) scrubbers to convert SO2 in the flue gas to carbon dioxide. While this increases greenhouse gases released to the atmosphere, it removes the SO2 that causes acid rain.

With all the coal-fired power plants now in existence and the number of new plants in planning stages around the world, the market for FGD systems is growing rapidly. According to the McIlvaine Company, power plants will spend $168 billion for FGD systems between 2005 and 2020. Of the 2.2 million megawatts of coal-fired plants in operation in 2020, two-thirds will be equipped with FGD systems.

Scrubber Technology

FGD systems use either dry or wet scrubbers. Dry scrubbers use lime or limestone as a reagent to remove SO2; although they use water in the process, the water usage is lower than with wet scrubbers. When the power plant’s coal contains less than 2% sulfur, as it does in the U.S. West, the plant will typically consider using dry scrubbers. Wet scrubbers are preferred when the coal contains higher amounts of sulfur. These scrubbers use an absorber tower in which flue gas is contacted by the limestone slurry, resulting in conversion of SO2 in the flue gas into calcium sulfate (gypsum), with carbon dioxide (CO2) going up the stack. This article will focus on treating the purge stream from wet scrubbers.

The U.S. power industry alone produces over 120 million tons of coal utilization byproducts (CUBs) per year. CUBs consist of fly ash, boiler ash and FGD sludge. About 30% of CUBs produced by U.S. coal plants are used in commercial applications, reducing waste to be buried in landfills. For FGD sludge, these commercial applications include wallboard-grade gypsum and lesser quality gypsum used in the cement industry or for landfill stabilization.

To maintain required conditions in the scrubber, a constant purge stream is discharged from the scrubber system. The FGD purge stream contains pollutants from coal, limestone and make-up water. It’s acidic and supersaturated with gypsum, with high TDS, TSS, heavy metals, chlorides and dissolved organic compounds.

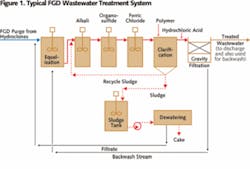

Treating the Purge

The scrubber purge stream is treated in a dedicated wastewater facility rather than any existing treatment system, for the following reasons: