Photo ll. GDT Process - O3 Transfer & Degas

In the spring of 2000, GDT Corp. was contacted by a southern Arizona manufacturer of powder and liquid milk and soy products to discuss the merits of retrofitting the plant’s cooling tower with an ozone treatment system. The cooling system consisted of a 4,400 ton fiberglass, induced draft cooling tower supported by a 114’ x 30’ concrete sump containing 51,000 gallons of evaporative cooling water. A secondary 20,000-gallon concrete basin, positioned centrally along the length of the tower basin’s northern wall, served as a deep wet well, providing a 10’ net positive suction head (NPSH) for the cooling tower’s 13,200 gpm recirculation pumps. Tower makeup water was provided by the facility’s reverse osmosis system. The high purity, low solids of the RO water allowed the plant to operate the cooling tower at 10 cycles of concentration, resulting in a minimal bleed off of the total water consumed by the evaporative tower. A small, 250 gpm sidestream basin sand filter, located at one corner of the tower sump, provided minimal removal of suspended solids.

Background

The chemical water treatment program consisted of a blended phosphate/molybdate corrosion inhibitor, injected into the cooling water to maintain a molybdate concentration within a range of 1.5-2.5 mg/L (measured as MO+6 using the mercaptoaceitic acid method). Inhibition of microbiological fouling was accomplished by the injection of a 1.6% solution of Isothiazolin in direct proportion to the cooling tower makeup rate. Bleach was slug fed during summertime operation to reduce algae growth. Service reports provided by the chemical treatment provider showed heterotrophic plate counts (HPC) of <1.0 x 103 per ml and corrosion rates of 0.4 mpy (mils per year) on mild steel coupon specimens and 0.1 mpy on copper coupon specimens.

Ozone Dosage

An applied ozone dosage of 5 grams per hour per 100 (peak) operating tons was specified as a sufficient dosage for the food plant’s cooling tower. The ozone dosage was based on the following operational factors:

• Tower make-up water quality.

• Tower bleed-off rate.

• Summertime operating loads.

• Basin sun exposure.

• Basin suspended solids loading.

• Filtration capacity and performance.

Injection & Off Gas Control

The proposed ozone injection system was designed to address concerns regarding the possible exposure of the plant’s water treatment staff to ozone off gas and the potential for ozone gas to cause structural corrosion of metal support structures and the delaminating of the tower’s fiberglass structures.

Source: SPX Cooling Technologies

A pre-basin pressurized mass transfer and degas system was ultimately selected as the best method to insure efficient ozone transfer into solution without the expelling of excessive ozone off gas at the cooling tower basin. The 265-gpm injection system utilized the GDT process, which included a Mazzei 3090 injector, a pressurized 316 SS reaction vessel and a GDT DS-300WM degas separator and a degas relief valve with a demister and ozone off gas destruct (see Photo II).

Basin Distribution Concerns

The design of the basin distribution system addressed two issues that were problematic with the distribution of a small, concentrated, dissolved ozone stream into a large, atmospheric water basin.

The first issue of concern was the potential of desaturation of the dissolved ozone gas stream prior to its dilution into the shallow tower basin. A drop to atmospheric pressure at the degas separator outlet would result in dissolved gas de-saturating into bubbles within the PVC pipe connecting the separator to the basin’s distribution manifold. The result would be excessive ozone off gas at the basin. To prevent desaturation of the concentrated ozone stream that would cause ozone off gas, the basin manifold was designed to maintain pressurized water conditions within the PVC pipe until the concentrated, dissolved ozone stream could be discharged into the tower basin.

The second issue of concern focused on the need to thoroughly mix the dissolved ozone stream into the tower basin. Insufficient mixing would leave areas of untreated basin water and result in breeding zones where algae and bacteria could thrive. Anecdotal information from the plant operators indicated that a substantial biological breeding zone already existed within the sediment that collected at the basin floor. During their annual tower cleaning, protective gear was worn to prevent direct contact with the sediment, which existed as a black sludge that gave off a rotten egg odor.

Ozone Transfer Efficiency

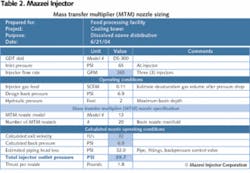

Ozone contacting pressure was set at 30 psig, to optimize ozone transfer efficiency (see Table 1). To rapidly proportion and mix the 265 gpm concentrated ozone stream across the 3,420 square foot tower basin, a 2” PVC manifold was placed along the basin’s perimeter wall and fitted with 20 Model No. 13 Mazzei Injector TurboMixer® nozzles. Nozzle placement and orientation was designed to sweep the basin floor on all sides with high velocity discharge plumes of 32 ft/second The ozone system’s final design was approved and installed by late spring of 2001. The system consists of a 240 g/hour air fed ozone generator (see Photo III), a GDT pressurized contacting and degas system (see Photo II), and a Mazzei distribution nozzle manifold to distribute dissolved ozone across the 3,420 square foot basin. An ORP controller monitor was provided to control the applied ozone dosage based on the mV reading of the tower basin water.

Ozone System Performance

To insure against excessive corrosion rates, an open market molybdate based corrosion inhibitor was selected as the primary tower corrosion inhibitor. The feeding of the new inhibitor was based on maintaining a tower water molybdate concentration (tested as MO+6) of 2 mg/L. Due to recent restrictions on molybdate discharge, the plant has since switch to a phosphate based inhibitor.

Photo lll. Ozone Generation - Compressor, Dryer, Ozonia O3 Generator, O3 Air Monitor

During the first six months of tower operation (July-December 2001), the ozone dosage was controlled by maintaining a tower water ORP reading of 500-600 mV. Corrosion rates on mild steel and copper measured 3.02 mpy and 0.39 mpy respectively. HPCs ranged from 4.0 x 103 per ml during summer operation to <100 per ml during the lower cooling loads of winter. The Hach Barts test for anaerobic corrosive bacteria consistently showed a non-detect reading, i.e., 0 colonies.

Throughout 2003, equipment inspections confirmed clean heat transfer surfaces and good corrosion protection. Corrosion rates throughout 2003 averaged 1.4 mpy on mild steel coupon specimens and 0.21 mpy on copper specimens. HPCs remained <100 per ml and pressure and temperature drops across critical heat exchangers remained stable, indicating clean heat transfer surfaces and good heat transfer efficiency.

The return on the plant’s investment in the GDT packaged ozone system was less than one year. The switch from a traditional chemical treatment program to an ozone program utilizing an open market corrosion inhibitor reduced treatment costs from $70,000 in chemical cost to less than $7,000 per year in chemical and electrical costs. Basin sediment, which previously accumulated as a sticky, black, odorous sludge now exists as an odorless, sandy sediment. The labor hours for basin cleaning have dropped by 30% and plant personnel are less concerned about the health risks associated with tower basin cleaning.

Conclusion

To summarize:

• Ozone in combination with open market chemical inhibitors substantially reduce cooling tower treatment costs.

• Ozone can play an important role in preventing microbiological induced corrosion and fouling of a cooling tower’s critical heat exchangers.

• Ozone can reduce tower basin cleaning and minimize the health risks associated with basin sludge removal.

• Ozone can be efficiently transferred into a shallow basin by utilizing pressurized sided stream contacting in conjunction with a well designed basin distribution manifold.

• The hazards of ozone off gas production at tower basins can be eliminated by utilizing a pressurized sided stream degas separator. IWW

About the Author: Jim Jackson is water & wastewater systems manager for Mazzei Injector/GDT Corp. of Bakersfield, Calif., which specializes in ozone applications. He has over 25 years of industrial water treatment experience. Contact: [email protected].