Maintenance Issues for Water Storage Tanks: Inspections and Circulation

by Danette D. Sutton

Your water storage tank is one of the most valuable assets at your facility. The American Water Works Association (AWWA) has guidelines in place to ensure your tank is kept at its most optimal level of operation. We're going to explore two very important issues, which during the rush of other daily tasks, are sometimes overlooked. One is routine inspections and the other is water circulation.

Inspections

According to AWWA M42, tanks need to be inspected by industry professionals on a regular basis to ensure structural and sanitary integrity. These inspections should also include washouts once every three years unless you are in an area prone to sediment problems than annual washouts are recommended. In addition to routine inspections, every tank repair job should be preceded by a detailed inspection of the structure and a report performed by a qualified inspector.

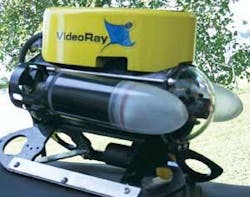

There are generally two options for inspection – dry and ROV (remote operated vehicle). Dry is just as it sounds. All water is removed from the tank and qualified inspection personnel enter tank to conduct the internal inspection in accordance with AWWA guidelines. Depending on the source of your water, this method will require the loss of water and may include an expense associated with re-filling the tank. An ROV option, which doesn't require draining the tank nor the lockout/tag-out procedures associated with divers, fully meets AWWA inspection requirements with a better solution.

The ROV is controlled by qualified inspection personnel trained to use this equipment. By this method, you or your representative can view, live, the inspection via monitor and speak directly with the inspection personnel. Just as with the dry inspection, all aspects of your tank are checked – structural, safety and coating condition. With either method, a written detail report of findings with photographs, corrective recommendations and cost estimates should be provided to you. The ROV method often includes a DVD.

Incidentally, you should make sure all submergible equipment is fully disinfected before being placed into the tank. Obviously, when it's time for the tank to be washed out, draining will be required. A pressure relief valve or a temporary tank, however, are options available to allow for tank bypass while still maintaining adequate water service to your customers.

Circulation

Circulation is the key to preventing stratification of the water within a tank. As a side note, with proper circulation and water turnover, freezing of potable storage tanks should not occur.

Typically, water is added and drawn from the bottom of the water container through inlet and outlet piping. When the fill rate is greater than the draw rate the water level rises. When the draw rate is greater than the fill rate water level lowers. If the fill and draw rate remains consistently equal than the system is drawing the water just added. What results is the water at the top of the container sits with no circulation leading to stratified and stagnant water. Also the chlorine which remains in the stagnated water can become depleted, leading to microbial growth as well as tastes and odors. A common and economical way to prevent this is to extend the inlet up to the mid-point capacity level. Thus, mixing occurs as water is put into the tank. With this approach no internal mechanical equipment is necessary.

We hope the above information assists you in making the best decisions for your tank.

About the Author: Danette D. Sutton is in the Maintenance Sales Division of Pittsburg Tank & Tower Co. Inc., which provides services for fire protection and potable steel storage tanks in the public and private sector. The Henderson, KY-based company performs inspections using "Odyssey" 1 & 2 ROV units and circulation system installations. Contact: 270-826-9000, [email protected] or www.watertank.com