Mining Wastewater for Hidden Treasures

Remediating metals from industrial wastewater provides saleable product and clean water at the same time as it eliminates odor problems

by Brad Marchant

On the surface, the towns of Breckenridge, CO, and Blackwell, OK, seem to have little in common. But both share a significant environmental concern – metal contaminated water caused by past mining and industrial activity in those areas. And both places will soon benefit from the same water treatment solution developed by BioteQ Environmental Technologies, a Canadian-based water treatment company that removes metals and sulphate from contaminated wastewater.

In the case of Breckenridge, a picturesque ski town nestled in the Rocky Mountains of Colorado, groundwater is contaminated with cadmium and zinc from the Wellington Oro zinc-silver mine that closed in the 1970s. Surface drainage from the mining area produces an acidic wastewater that requires treatment before discharge to the French Gulch tributary of the Blue River.

The Wellington Oro site was selected by the U.S. Environmental Protection Agency as a Superfund site for remediation. In 2004, the EPA issued an international call for proposals to find the best available technology to treat the problem, and selected BioteQ as the successful bidder. After consultation with the community, the EPA and the town of Breckenridge are proceeding with construction of the water treatment plant, which BioteQ has designed to treat acidic wastewater and remove zinc, lead and cadmium to very low levels using its proprietary ChemSulphide™ process. Water treatment will allow re-establishment of a fishery downstream of the operation, and will recover a zinc-rich concentrate product that can be shipped offsite for final refining. The BioteQ plant will not produce any waste sludge that requires long term storage.

At Blackwell, groundwater is contaminated with zinc and cadmium originating from an abandoned smelter site, now owned by Phelps Dodge. Phelps inherited the site through a takeover of Blackwell Zinc Co., and immediately recognized the need to find a solution to the groundwater contamination. Following a detailed review of treatment process options and consultation with the Oklahoma Department of Environmental Quality, Phelps turned to BioteQ for a solution. Phelps has worked with the company previously at its closed mine site in Bisbee, AZ, where the companies have a joint venture to treat metal-laden acidic wastewater; revenues from the copper recovered pay for the water treatment. Based on this experience, Phelps knew that BioteQ’s sulphide technology could remove the toxic metals and meet stringent water quality criteria at the Blackwell site to provide a long term treatment solution. The plant has been constructed, and awaits commissioning, pending the site schedule set by Phelps Dodge.

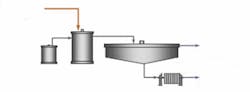

The ChemSulphide™ process uses chemical sulphide reagents to remove and recover metals from contaminated water while BioteQ’s BioSulphide® process uses hydrogen sulphide (H2S) gas generated biologically at the treatment site. In both cases, sulphide is introduced to a contactor tank that contains the contaminated water to be treated; the solution chemistry in the tank is adjusted to selectively precipitate metals as pure metal sulphides. The precipitated metals and treated water are pumped to a clarifier tank where the clean water is separated from the metal solids and either discharged to the local environment or recycled. The metal solids are filtered to remove excess water, producing a high grade metal product suitable for refining. To recover multiple types of metals, separate contactor and clarifier tanks are set up in series. The outputs are saleable metal products and clean water that can be discharged to the environment.

Historically, metal-laden acid water has been treated with lime. While lime treatment removes metals from water, it also creates a toxic sludge that requires ongoing management and storage, creating a long-term liability for mining firms. BioteQ’s process, on the other hand, provides a sustainable solution for metal-laden water as it eliminates sludge and the associated environmental liability, produces clean water and saleable metals, and is less expensive than lime treatment. Sale of the metals recovered can offset the water treatment costs.

About the Author: Brad Marchant is CEO of BioteQ Environmental Technologies Inc., a Vancouver, Canada-based company that builds, owns and operates water treatment plants for the world’s mining companies and utility operators, reducing environmental liabilities while generating revenue from waste. BioteQ’s technology treats acid mine drainage and other metal-laden wastewater by sequentially removing metals and sulphate. The company provides plants as a joint venture partner, as a build-own-operate service provider, or as turnkey plant sales like the ones in Breckenridge and Blackwell. It’s currently constructing five new plants in China, Australia, Mexico and the United States. Contact: 604-685-1243, [email protected] or www.bioteq.ca