By David Pearson

Evaporators are used extensively in the dairy industry as a method of removing water from a fluid to obtain a more stable or reduced volume product. Often, the resulting concentrate is subsequently dried to a powder.

The water condensed during evaporation is hot and may contain a small amount of the product itself. This "carry over" in the vapor is due to splashing or boiling of the product during the evaporation process, which creates a mist of tiny particles that can be distilled over into the condensate along with the water. For this reason, the evaporator condensate – although relatively pure – can contain enough organic material to support bacterial growth when cool. This makes the condensate unacceptable for re-use in any food-related environment.

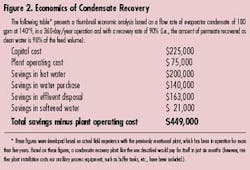

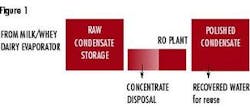

One dairy processor, however, recently began filtering evaporative condensate through a reverse osmosis (RO) membrane (see Figure 1), thus discovering a valuable source of hot, good-quality rinse water. Based on energy, freshwater, effluent disposal and other cost savings, this system effectively paid for itself in just six months (see Figure 2).

Compared with conventional water treatment systems, an RO plant requires relatively little space (about 30x10 feet for the system referenced here) and often can be custom designed to fit into the existing available space on site, so normally there's not a need for plant expansion to accommodate the condensate recycling system. Other advantages can be summarized as follows:

• Energy saving – Recovering the hot condensate for re-use captures valuable heat energy that might otherwise be lost in disposal to drain or effluent treatment, value typically $13.90 per 1,000 gal.

• Water cost saving – The volume of water recovered via RO can be used in place of purchased fresh water, value typically $3 per 1,000 gal.

• Wastewater disposal costs saving – RO allows up to a 90% reduction in the volume of effluent sent for disposal that, depending on the effluent loading and location, can have a value of $3.50 per 1,000 gal.

• Softened water saving – Recovered water (the RO permeate) is a source of good quality softened water. This reduces the cost associated with softening incoming municipal or well water, as well as the cost of disposing of regeneration chemicalsU value typically $0.45 per 1,000 gal.

Conclusion

While the RO condensate recovery system can reduce the volume of condensate effluent sent for disposal by as much as 90%, the remaining effluent concentrate (the RO retentate) may be sent either to an existing effluent treatment site or to drain. Assuming that much of the cost of effluent disposal is attributed to the water volume, and not BOD (biological oxygen demand) loading, there are considerable savings to be achieved, even if the concentrate is passed to drain.

About the Author:

David Pearson is general manager of PCI Membrane Systems Inc., a unit of ITT Sanitaire based in Milford, OH. PCI specializes in tubular membranes for use in treatment of liquids with suspended, colloidal or viscous materials. It also supplies spiral-wound or hollow fiber membranes for clean solutions and ceramic membranes for high chemical compatibility and thermal resistance. Pearson can be reached at 513-575-3500 or www.pcims.com