By Mark Reinsel, Ph.D., P.E.

PPL Montana requires a method to reduce water volume in its Colstrip, Mont., process ponds through water management (reuse) and/or water treatment, which would alleviate regulatory concerns about pond seepage and allow the company to implement a paste technology for solids disposal. Paste backfill is popular in the mining industry.

Eleven options were initially considered for water reuse and treatment. Five viable options were developed and their effects on the existing water balance, advantages and disadvantages, estimated costs, and projected timeline for implementation and treatment were estimated. Two alternatives were considered for four of the options – one to treat pond water and another to treat cooling tower blowdown (CTBD). Using budgetary annual operating costs and installed capital costs, net present values (NPVs) were calculated for three and five years.

Background

At the time of this study, approximately 4,000 acre-feet of water were contained in a series of process ponds at PPL Montana's Colstrip site. One set of ponds is associated with Units 1 and 2; another set is associated with Units 3 and 4.

The first concern created by the volume of process water in these ponds is an environmental issue. A high inventory of water has the potential to increase seepage from the ponds, which is captured by pumpback wells. Since the site is permitted as a zero-discharge facility, plant management is concerned about this seepage and sought a long-term solution. Potential solutions include modifying the ponds and dams to mitigate seepage losses, modifying the way process waters are handled to reduce hydraulic head on the underlying strata so seepage from the ponds is reduced, or treating the water to reduce the inventory.

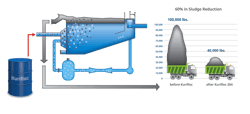

The second concern is a process issue. PPL was evaluating a "paste" technology which it hoped to implement on a full-scale basis. The paste technology would increase the percent (%) solids of the slurry sent to the process ponds, thereby substantially decreasing the amount of water sent to the ponds and simplifying water management in the disposal cells. It's necessary, however, to reduce the amount of water in the ponds prior to converting to this technology, so that the paste can be deposited in a "dry" cell rather than subaqueously. To address these two concerns, PPL required a method to reduce the water volume in the process ponds through water management (reuse) and/or water treatment.

Click here to view Table of Best Treatment Alternatives.

This article describes evaluation of the following potential treatment and water management options:

• Directly reusing process pond water in more areas of the process;

• Using a reverse osmosis (RO) system for process pond water or CTBD to reduce raw water requirements;

• Using an evaporator or crystallizer for process pond water or CTBD, which would reduce pond inventories and produce high-quality water for reuse; and

• Expanding use of turbo mist evaporators in the process ponds.

Treatment Options Considered

After analyzing information from a site visit, treatment options were considered along with their effects on the process and their effect on the primary goal of this project, the volume of pond water. The first step was to construct a schematic of the current water balance at the Colstrip facility (see Figure 1). This water balance served as the baseline to which all treatment options were compared.

According to plant personnel, this water balance currently provides a "steady state" regarding the pond water volume; i.e., the pond water levels are now fairly constant. About 2,050 gallons per minute (gpm) is now being lost between the scrubbers and ponds. This is due to evaporation in the scrubbers, natural and enhanced evaporation in the ponds, and water contained in calcium sulfate and other sludges. Any changes to the water balance that reduce this flow to less than 2,050 gpm should reduce the pond water volume, which was the goal of the project.

The following options were considered:

1. Additional recycle of pond water to replace raw water for some uses, which would reduce the pond water volume. It may be possible to use pond water as seal water – this requirement is approximately 600 gpm. It may also be possible to use pond water in the scrubber lime system (used for cut-off sprays and grit washers), which has a requirement of about 150 gpm.

2. An RO system for pond water. A used system, which was available and would be most economical, would treat high total dissolved solids (TDS) water at a recovery rate of 30-40%. This would not be a complete solution to PPL's pond water inventory but is one method to dispose of about 100 gpm, which would be recovered as relatively high-quality water.

3. Lime-soda softening to remove calcium and magnesium from pond water. The disadvantages of this system, which include high operating costs for chemicals, a large quantity of sludge produced and a minimal improvement in overall water quality, preclude its consideration as a viable treatment option for pond water. However, softening in combination with RO will be considered in other options.

4. Lime softening to remove magnesium only. This system would have lower operating costs but the same disadvantages as Option 3 above, so it was also eliminated.

5. Lime-soda softening plus treatment through RO. It was believed that the patented High Efficiency Reverse Osmosis (HERO™) process – designed by any of several companies under license from the patent holder Deb Mukhopadhyay – may be the best RO option. The process maximizes recovery (over 90% for some feed waters), and minimizes operating costs by completely removing hardness through weak acid cation ion exchange and by operating the RO at high pH.

The high hardness of pond water, however, substantially increases operating costs for this process, reduces the recovery that's possible and reduces the quality of water produced. Therefore, the HERO process was eliminated from further consideration.

6. Lime-soda softening followed by a conventional RO system. This would be a simpler, less expensive treatment system than the HERO process for this type of water.

7. Lime-soda softening for cooling tower make-up (all raw water fed to the cooling towers), followed by the HERO process for CTBD. For the same reasons mentioned above for Option 5, this option was eliminated.

8. Lime-soda softening for cooling tower make-up, followed by conventional RO for CTBD. Although this does not treat pond water, it could reduce the pond water volume by altering the water balance around the pond. Due to high costs and process constraints (the elimination of CTBD for use in the turbo mist eliminators), this option was also eliminated.

9. A new evaporator (brine concentrator). An existing brine concentrator, which was shut down in 1998, was not considered for further operation because of its age (about 25 years) and the fact that much of the equipment has been dismantled. A new evaporator, however, is a viable option.

10. A new crystallizer. A crystallizer concentrates water more than an evaporator, and produces dry solids along with a relatively small amount of concentrated brine. A crystallizer may be preferable to an evaporator when treatment waste must be reduced to a minimum, with a trade-off of higher energy costs. PPL Montana, however, has ponds available for concentrated brine from an evaporator, so it would probably not be cost-effective to reduce the brine volume through crystallization (higher energy costs). Therefore, a crystallizer was eliminated from further consideration.

Conclusion

Three-year NPVs for the best treatment options ranged from $15,000 to $16 million. A lower NPV increases the viability of an option. Short-term treatment options could be implemented in as little as one to two months, while the longest lead time required was 12 months. Under the scenarios considered, treatment times of three to five years would be required to reduce the pond water inventory at Montana PPL's facility to 10% or less of its present value.

About the Author: Mark Reinsel, Ph.D., P.E., is president of Apex Engineering, PLLC, a small consulting firm in Helena, Mont. Dr. Reinsel has 20 years of experience in consulting, industry and academia. His recent projects have focused on treating industrial waters and drinking water through chemical, physical and biological methods (both active and passive). He received his doctorate in chemical engineering from Montana State University.