An Overview of Coal-Fired Power Plant FGD Wastewater Treatment - Coal Combustion and Emissions Control

Coal, the primary U.S. resource for producing electricity, generates over half the nation’s electricity. Balancing a dependence on foreign oil, coal offers over 274 billion tons of untapped supplies - enough to energize America for 250 years. According to The Energy Blog, The National Coal Council (NCC) released a study recommending maximized usage of coal to generate electricity over the next 20 years. Coal combustion in power generation facilities results in energy release, solid waste produced as bottom ash and fly ash, and flue gas emissions to the atmosphere. Suspended particulate matter, or fly ash in flue gas, is controlled through electrostatic precipitators (ESPs) and/or baghouses. ESP performance may be enhanced by adding ammonia to the flue gas.

The primary gas emissions are criteria pollutants (e.g., sulfur dioxides [SOx], nitrogen dioxides [NOx], particulate matter, carbon monoxide and others). About two thirds of all SOx and a quarter of all NOx in our atmosphere come from electric power generation, achieved by burning coal and other fuels. SOx causes acid rain, and NOx creates atmospheric ozone. Secondary emissions, such as mercury, arsenic, selenium, and boron, are indigenous to the type of coal being combusted. Clean Air Act Amendments regulate many of these pollutants, and require stringent controls of SOx and NOx emissions.

NOx compliance requires use of controls, such as: selective catalytic reduction (SCR), selective noncatalytic reduction (SNCR), and low NOx burners. Both SCR and SNCR cause ammonia slip, which allows unreacted ammonia to slip past the NOx control device for subsequent removal in the electrostatic precipitator or scrubber. If the water is discharged to an ash pond, this ammonia may oxidize to nitrite and nitrate.

SOx compliance mandates use of flue gas desulfurization (FGD). The three methods used in the U.S. to desulfurize flue gas include wet scrubbing (85%), dry scrubbing (12%), and dry sorbant injection (3%). Wet scrubbers (see Exhibit 2) achieve SOx removal efficiency of greater than 90%, compared to dry scrubbers at 80%.

Wet Scrubbing FGD

This article focuses on the wet scrubbing methods used to desulfurize flue gas in coal-fired power plants. Three main scrubbers used for wet scrubbing - venturi, packed and spray scrubbers - are characterized by the following treatment steps:

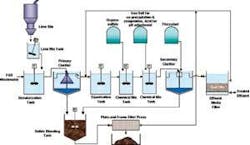

Exhibit 5 depicts a wastewater treatment scheme developed by CH2M Hill to treat FGD wastewater and remove heavy metals. In this particular plant, it was decided to desaturate the wastewater of sulfates and remove the bulk of the insoluble suspended solids prior to tertiary treatment of heavy metals and arsenic using a chemical/physical treatment process. Additional treatment could be provided (i.e., anoxic biological treatment) for selenium, nitrates and organics. This system didn’t require that level of treatment to meet NPDES permit requirements.

Tertiary treatment is target-pollutant specific. Metals can be treated through chemical, physical and biological means. Iron co-precipitation removes cationic metals and arsenic. Adding organosulfide precipitants lowers levels of cationic metals such as mercury. Selenium, particularly the oxidized form (selenate, the principal form of selenium in forced oxidation scrubbers), can be treated through biological processes (i.e., anoxic biological treatment processes and/or constructed wetlands). Organics can be treated through the same processes if properly designed. Careful consideration of chemical and biochemical stoichiometry of the pollutants, as well as temperature, pH, and TDS is required in the process design.

Conclusion

CH2M Hill completed conceptual evaluations, treatability test programs, preliminary engineering designs, and detailed designs to treat FGD wastewater at several different coal-fired power plants. While completing this and other ongoing FGD wastewater treatment work, it identified several key issues that should be considered in designing infrastructure for FGD wastewater: