Refinery Benefits from Municipal-Industrial Water Reuse Project

Hampton Roads Sanitation District (HRSD) set a goal to reuse its treated wastewater for non-potable purposes in the 1980s. The district was created in 1940 to reduce pollution in the Chesapeake Bay. It currently serves a population of about 1.6 million with nine regional wastewater treatment plants in Hampton Roads and four smaller plants on Virginia’s Middle Peninsula, just north of Norfolk, VA.

An oil refinery located next to its York River Treatment Plant approached HRSD in 1996 to supply reclaimed water for the refinery’s cooling and process water. Previously, the refinery used increasingly expensive potable water - and upgrading its own treatment facilities was too large an investment. In December 2000, HRSD signed a 20-year agreement to provide the refinery with 0.5 mgd of reclaimed water. This was Virginia’s first municipal-industrial water reuse project.

System Considerations

Since the existing activated sludge treatment process at HRSD’s York River Treatment Plant couldn’t reliably meet the refinery’s special target requirements for both low turbidity and ammonia concentration year-round, other treatment processes had to be identified. HRSD first investigated filtration technologies for enhanced solids removal. Following a pilot study in 1998, it installed a 4-disk AquaDisk® cloth media filter from Aqua-Aerobics Systems Inc.

HRSD chose the cloth media filter over a sand media filter because of its smaller footprint and operational advantages. It then researched several secondary treatment processes and decided to install a single-basin AquaSBR® system fed with primary clarifier effluent to produce year-round biological nitrification. This sequencing batch reactor (SBR) system was chosen for its reliability and cost effectiveness. The reclamation operation began in July 2002. The reclaimed water system is designed so that fully treated water can be fed to the cloth media filter from either the full-scale plant effluent or the sidestream SBR system.

The SBR Process

The SBR system operates on a simple concept of introducing a quantity of waste to a reactor, treating the waste in an adequate time period, and subsequently discharging a volume of liquid effluent plus waste sludge that’s equal to the original volume of waste introduced to the reactor. This “fill-and-draw” principle of operation involves the basic steps of fill, react, settle, decant, and sludge waste. The system may be designed to include seven individual phases of operation but the inclusion or duration of any individual phase is based upon specific waste characteristics and effluent objectives.

Where nutrient removal is required, a simple adjustment to the SBR’s operating strategies permits nitrification, denitrification and biological phosphorus removal. Optimum performance is attained when two or more reactors are utilized in a predetermined sequence of operation.

The Filter Process

Clarified effluent from the activated sludge system enters the filter and flows by gravity through the cloth media of the stationary hollow disks. The filtrate exits through the hollow shaft that supports the individual disks and flows to the effluent channel.

As solids accumulate on the surface of the media, the water level surrounding the disks rises. Once a predetermined level is reached, the disks rotate and the media surface is automatically vacuum backwashed clean. Heavier solids settle to the bottom of the tank and are then pumped to a digester or to the plant headworks.

Design Characteristics

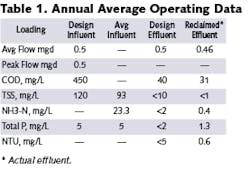

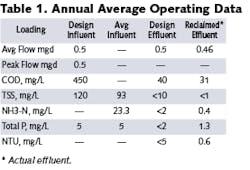

This single basin SBR system produces biological nitrification for the sidestream treatment process prior to entering the cloth media filter. The 4-disk cloth-media filter produces reuse quality effluent for discharge to the oil refinery for its cooling and process water purposes.

Since the start-up of York River’s sidestream process, the SBR system and cloth-media filter have consistently produced reclaimed water that’s higher quality than was required at the time of the reuse agreement in December 2000.

Conclusion

HRSD sells the reclaimed water to the refinery at cost, to recover only the additional investment of building and operating the sidestream treatment system and the filter. The total cost of the reclaimed water over the 20-year agreement period is approximately half that of potable water. Not only does this reuse partnership save the refinery money and provide a drought-proof water source, it also conserves natural resources and reduces nutrients otherwise released into the York River - and, ultimately, into the Chesapeake Bay.

This partnership has led to the receipt of two awards: the WateReuse Association’s national “Project of the Year” (2003) and “Honors Award for Engineering Excellence” (2004) from the American Council of Engineering Companies (ACEC) of North Carolina.

HRSD is pursuing other uses of reclaimed water which may lead to reuse projects at its other treatment facilities in the future. The possibilities include: boiler feed water, tunnel washing, and irrigation, to name a few.

Aqua-Aerobic Systems Inc. is based inRockford, IL. Contact: 815-654-2501, 815-654-2508 (fax), or www.aqua-aerobic.com.