Energy Efficiency, Cost Savings Drive Interest in Waste Heat Recovery

By Jeff Gunderson

A recent report by Global Industry Analysts (GIA) projected the global market for heat exchangers to reach $20.8 billion by the year 2018, primarily driven by rising energy costs, tightening environmental regulations and a growing global focus on energy efficiency. The report, "Heat Exchangers: A Global Strategic Business Report," found that the market for heat exchangers is poised for significant growth in the coming years with increasing investments in plant infrastructure and improvements in energy efficiencies emerging as a key differentiating factor for manufacturers to compete in the marketplace.

Heat exchangers are one of many available age-old technologies that can recover waste heat generated from industrial processes and operations -- energy that in turn can be utilized for a variety of end uses. Because of the potential for significant energy savings, more industrial manufacturers are recognizing the benefits of capturing and reusing waste heat that would otherwise go unused.

According to the U.S. Department of Energy, an estimated 20 to 50 percent of industrial energy input is lost as waste heat in the form of hot exhaust gases, cooling water, and heat lost from hot equipment surfaces and heated products. Captured waste heat -- which can be recycled within the same process or transferred to another process within the plant -- offers an attractive opportunity for an emission-free and less-costly energy resource.

As a sustainable practice, waste heat recovery can result in reduced energy consumption, and, in some instances, can help contribute to LEED certification. For example, among the numerous sustainable innovations of UC Davis' LEED Platinum Brewery, Winery and Food Science Facility is a water loop compressor cooler which is connected to water-source heat pumps, enabling the transfer of waste heat for space heating.

For industrial water-based systems, a growing number of technologies are being developed and used for recovering waste heat that can be transferred to process water streams for water or process preheating, boiler feedwater system preheating, building conditioning, or in wastewater treatment. In addition to heat exchangers, other options include recuperators, regenerators, economizers, heat pumps, and run-around coils, along with several more.

Among heat exchanger technologies, plate and frame, shell and tube, and falling film heat exchangers specifically enable for the capture and transfer of heat to liquids, including liquid to liquid heat exchanges. Another heat exchange option -- air-cooled heat exchangers -- is beginning to represent a viable solution as compared to longstanding industrial heat removal methods. Indeed, with water becoming a scarce and expensive resource, the GIA report forecasted robust future growth for air-cooled heat exchangers, which are emerging into a cost-effective alternative to cooling towers.

Waste heat recovery and transfer innovations are increasingly reusing captured heat more efficiently, said Brent Giles, a senior analyst at Boston, Mass.-based Lux Research. "Because of the potential for greater water process efficiencies, more industrial manufacturers are taking a comprehensive view of their process operations and implementing efficient heat exchangers and other waste heat recovery strategies wherever feasible," he said.

Anand M.G., a senior research analyst for Frost & Sullivan's Industrial Automation and Process Control group, said energy efficiency is a keen focus of the industrial sector, especially in regards to water and wastewater. "As water is the major working medium in various industrial processes, recovering energy from used water to heat newly-supplied water is a key process improvement strategy in energy management," he said. "And, as technology evolves, an increasing number of process and manufacturing plants are adopting a variety of energy optimization platforms, using waste heat or other parameters."

"What we are seeing is the ‘greening' of the industrial sector," said Rich Fitterer, a principal at global engineering company GHD. "Heat recovery systems are proven performers in terms of energy conservation but now these types of technologies are becoming even more attractive because of the potential to reduce greenhouse gas (GHG) emissions."

But while waste heat recovery systems are seen as increasingly beneficial, industrial manufacturers still have high expectations in terms of returns. "The payback criteria for these types of investments can be very short, sometimes as little as two years or less," Fitterer said. "However, that is now changing as GHG reduction becomes important for meeting company sustainability goals."

Applications

Across a number of industrial areas, companies are implementing regenerative heat exchange applications and strategies that recover waste heat from a variety of sources for transfer to outside processes for water heating or for creating chilled water through absorption refrigeration cycles. Industries implementing waste heat recovery applications include energy, pulp and paper, automotive, chemicals, metals, food and beverage, as well as numerous other manufacturing sectors including glass, cement, paint, pharmaceutical, and bioethanol.

"In combined heat and power plants, heat recovery technologies with absorption chiller systems can utilize waste heat from process stack gases for creating chilled water for process cooling," Fitterer said. "We are also seeing two- and three-stage economizers incorporated much more with boiler stacks, using hydronic loops through heat exchangers to transfer recovered heat. Even boilers with single economizers still have 300- to 400-degree exhaust temperatures. Heat recovery units can extract a considerable amount of heat from these sources for generating hot water."

Rather than using steam to heat water for process or cleaning operations, facilities can utilize heat recovery systems to get water to the desired end temperature or close to it, according to Fitterer. "This makes the whole boiler system more efficient," he said. "The key is to match up the recovered heat with the appropriate load or heat sink."

Heat exchange technology is also being used to extract heat from industrial wastewater. In Canada, Ontario-based RenewABILITY Energy Inc., develops and manufactures falling-film heat exchanger systems that reclaim and recycle a substantial portion of the heat energy that is typically lost in waste fluid in many industrial processes and operations.

Called Power-Pipe, the technology can be installed in virtually any industrial application where there is warm to hot wastewater and can recover up to 70 percent of wastewater heat for use in preheating incoming colder water.

"The technology really shines in situations where there is a dirty waste stream or wastewater with a high concentration of solids or fibers that would foul other types of heat exchangers," said Gerald Van Decker, RenewABILITY Energy president and CEO.

The double-wall, vented heat exchangers, which consist of multiple coils of copper tube wrapped together around a central copper drainpipe, have been used in numerous industrial operations, from food processing to textiles, according to Van Decker.

"For example, scalding tanks in poultry operations have a tremendous amount of hot wastewater that we can recover heat from," he said. "Furthermore, a double benefit can sometimes be realized where it is necessary to cool food product or provide quenching of wastewater. In these situations, the Power-Pipe systems can cool these streams while extracting valuable heat and reducing primary energy consumption."

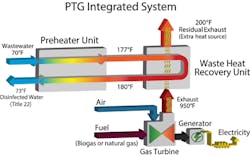

Another technology available on the market employs a specialized use of waste heat recovery, utilizing captured heat to disinfect wastewater. Developed by San Leandro, Calif.-based Pasteurization Technology Group (PTG), the technology is the first and only to combine sustainable wastewater disinfection with renewable energy generation.

PTG's integrated systems use digester or natural gas as fuel for driving a turbine to generate electricity. Hot exhaust air from the turbine, in turn, is passed through a waste heat recovery unit for increasing wastewater temperatures to a level that disinfects the wastewater stream.

"The technology is very aggressive in the use of waste heat," said Greg Ryan, CEO and co-founder of PTG. "First, shell and tube heat recovery is used for capturing and transferring exhaust heat to wastewater for disinfection. Then, that same energy is used again when the wastewater is subsequently passed through a plate and frame heat exchanger. The heat from the disinfected wastewater is transferred to the incoming stream, effectively lowering the temperature of the disinfected wastewater to a level that is acceptable for discharge or reuse in outside applications."

The PTG system is particularly effective in industrial operations that require a substantial amount of water and energy, including brewing and food processing, Ryan said.

About the Author: Jeff Gunderson is a correspondent for Industrial WaterWorld. He is a professional writer with over 10 years of experience, specializing in areas connected to water, environment and building -- including wastewater, stormwater, infrastructure, natural resources, and sustainable design. Jeff holds a master's degree in Environmental Science and Engineering from the Colorado School of Mines and a bachelor's degree in General Science from the University of Oregon.