"Pulsed" Systems Provide Latest Advance in UV Disinfection

By Robert M. Lantis And Chris Zanardi

In recent years, industrial water system managers have increasingly focused attention on the use of ultraviolet (UV) light to inactivate bacteria, volatile organic chemical compounds, viruses and other pathogens. As the safety risks and liabilities of chlorine, ozone and membrane breakage continue to burden these managers, UV technology has proven to be an attractive and effective alternative solution.

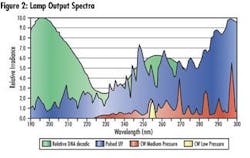

The most recent advancement in UV disinfection technology is the commercialization of a more distinct type of UV system based upon pulsed ultraviolet (PUV) lamps, which emit a polychromatic UV output across the entire UV-C band and deliver significant advances in both the safety and the performance of UV technology.

Most UV disinfection systems are mercury-based Continuous Wave (CW) output technologies. The new PUV technology does not use mercury to produce UV light. Rather, it produces UV by means of short, high-current pulses of electricity (up to 30 per second) through a harmless, inert xenon gas.

Unlike medium pressure mercury lamps, which must operate continuously at high quartz envelope pressures (several bar) and very high temperatures (600°C), the PUV lamp isn't pressurized and operates at a very low temperature, thereby eliminating the potential for an explosive and catastrophic release of mercury into water streams.

The enormous peak power per pulse capability of the PUV lamp (6,000,000 watts peak UV-C per pulse for PUV vs. 750 watts peak UV-C for typical continuous wave MP mercury lamps) delivers over an order of magnitude greater UV photon flux density upon pathogens, and at a greater distance from the lamp, thereby increasing the effective instantaneous UV penetration through the fluid, particles and pathogens.

UV output efficiency (and subsequently the UV dose) is consistent, because the output is neither dependent upon the lamp operating temperature, nor the associated temperature changes in the ambient cooling (influent) water. PUV lamps allow an instantaneous change in UV output across a power range from zero to 2,400 watts UV-C, but without the inherent UV efficiency loss associated with CW mercury lamps when departing from their particular optimum power and temperature operating points.

The power produced by PUV lamps is always in the form of consistent, quantifiable discrete pulses of UV energy; and it can be commanded in real-time with much greater precision, since the UV output is always simply a function of the pulse repetition rate at any instant.

While in order to produce large amounts of UV the instantaneous core temperature of the xenon plasma is very high, the short pulses and resulting low duty cycle of the PUV lamp allows the exterior cooling jacket temperatures to be very close to that of the ambient (influent) water. Therefore, the heat-induced mineral attachment mechanism (fouling) inherent with CW lamps is avoided, producing a UV source that requires neither mechanical cleaning attachments nor chemical cleaning/scrubbing maintenance.

Also, the very nature of PUV is "instant on" and "instant off", negating the need for system warm-up and temperature stabilization prior to operation.

The ultra-short pulse length characteristic and subsequent low-duty cycle of PUV allows a UV detector to measure the full-time operation of a UV reactor with a total detector UV exposure time of less than one minute over an entire 24-hour day (i.e., < 0.07 percent duty cycle). This is in contrast to the constant, 24-hour detector exposure (i.e., 100 percent duty cycle) of CW UV, which causes degradation of the optical component of the UV sensor, known as "solarization", negatively affecting its accuracy, repeatability and lifetime.

Case Study

The LSi water disinfection unit by LightStream Technologies, of Reston, VA, integrates PUV light with digital operating systems and touch screen operation, creating a "plug & play" disinfection machine that uses no chemicals and contains no mercury. Key features of the LSi system include:

– Self-enclosed stainless steel unit construction

– A single xenon flash lamp mounted in a closed vessel reactor

– An operator touch-screen interface that allows users to set flow, UV dose requirement and monitor system performance and system alerts

– The ability to run on 380 to 480 vAC, 3-phase 50/60 Hz Power

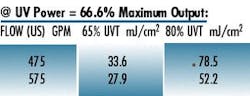

Using Constant Optimum Dose (COD) methodology, the unit conducts continuous sub-second analysis of the water's UV transmittance and performs instant adjustments to the lamp's UV power to deliver the specified UV dose. The rated flow-range over which the unit automatically maintains a set COD is 200 gpm to 700 gpm.

The LSi system was submitted to Hydroqual, Inc., of Mahwah, NJ, on Sept. 18, 2002, for the purpose of measuring the unit's UV dose delivery performance as a function of hydraulic loading by means of industry standard bio-assay methods.

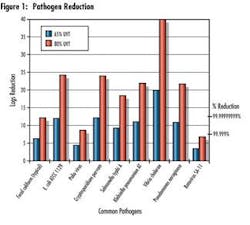

Hydroqual used MS2 coliphage as the challenge organism to estimate the system's germicidal dose-delivery capabilities at two different UV254 water-transmittance levels, 65% and 80%. See related charts.

By applying a good curve fit to the HydroQual-reported data sets, and then considering widely published data regarding the typical UV dose required for a particular log-reduction of micro-organisms, it is reasonable to expect significant inactivation rates for common pathogens.

Summary

Whether it be for the power, pulp & paper, pharmaceutical, semiconductor, agricultural, oil & gas, food processing or beverage industry, PUV can be used as the primary disinfectant in a variety of wastewater and process water applications.

As the industrial water treatment industry continues to move towards UV disinfection, pulsed UV technology provides industrial water system managers with significant advances in the precision and performance of UV systems. In addition, because PUV delivers disinfection without the use of chemicals or mercury, many of the safety concerns and liability issues associated with mercury UV and other disinfection methods are eliminated.

About the Authors: Robert M. Lantis is Chief Technology Officer and Chris Zanardi is Senior Marketing Manager of LightStream Technologies Inc. Zanardi can be reached at 703-480-2467 or [email protected].