Certified accurate: MCERTS inspectors & process instrumentation

Of all the world’s water, only 3 percent of it is freshwater. Rivers, lakes, groundwater and ice — that’s all we have for drinking, growing food and raising animals. So when the U.K.’s Environment Agency of England & Wales Monitoring Certification Scheme (MCERTS) inspectors arrive at a water or wastewater facility, they are fully aware of the important task set before them: to ensure accurate flow measurement to enable proper water treatment.

With help from process instrumentation and rigorous inspection techniques, SIRIS Environmental in Sunderland, U.K., aims to do just that every day.

First things first in wastewater

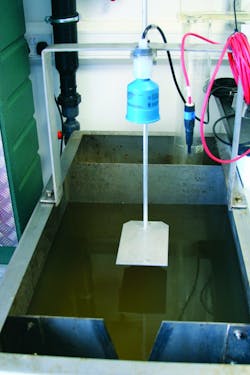

Inspectors install a target reference plate directly below the measuring device — in this case an ultrasonic transducer.

Flumes and weirs are primary measuring devices that millions of megaliters of water flow through each day in wastewater treatment plants (WWTPs).

However, with continual buildup adding itself to every part of these open channels, WWTP operators need more precision.

Open-channel monitoring by process instrumentation provides operators with the information they need to begin the wastewater treatment process.

With ultrasonic transducers mounted above a channel, connected to a high-precision controller, the water height — or head level measurement — is within 1 millimeter, and an accurate flow rate can be calculated.

Eight percent is the magic number for MCERTS inspectors. Over a 24-hour monitoring period, technicians must take 96 readings of wastewater effluent flowing through a flume or weir — in other words, one reading every 15 minutes.

These measurements are averaged and compared to the flume or weir’s calculated measurement — or what the ideal flow volume would be without the effect of any buildup on the flume or weir.

If a site’s total "uncertainty budget" is at or below

nt, the WWTP’s open-channel system will pass inspection and be issued an MCERTS Compliance Certificate. If it is higher, the site will fail. In that case, MCERTS inspectors will provide the WWTP with a list of recommendations to be used in preparation for a follow-up inspection.

Instrumentation inspection

Since water and wastewater treatment facilities depend so heavily on process instrumentation at every step of their operations, part of the inspection duties include close evaluation of a site’s open-channel monitoring system.

A sun shield installed over the ultrasonic transducer helps increase accurate open-channel readings by reducing temperature fluctuations caused by sun exposure. | All images courtesy of Siemens AG

Inspectors place a target reference plate in the path of a level measurement sensor and then compare the actual distance to the one reported by the level measurement device.

For example, with an ultrasonic transducer mounted above an open channel and connected to an ultrasonic controller, inspectors would find an extremely precise reading.

An ultrasonic system can be extremely accurate, measuring with 1-millimeter accuracy. Inspectors include the difference between actual and reported distance as part of a site’s uncertainty budget. Precise instrumentation with high repeatability is therefore an important piece of a WWTP’s overall MCERTS score.

In addition to installing reliable level measurement devices, the use of a sun shield is recommended above any instrument that is exposed to direct sunlight. The sun’s rays can affect an instrument’s readings by causing temperature fluctuations. A sun shield minimizes these types of fluctuations, helping the level system to provide more accurate measurements.

The demand for data logging

An ultrasonic controller can be installed quickly and in many mounting locations to save technicians time in setup and

programming.

For inspectors as well as for a WWTP, historical wastewater treatment information is extremely important. First, facilities must submit their effluent totals to local environmental agencies; failure to do so — or submitting information with missing records for a certain number of days — results in a fine for the WWTP.

For MCERTS inspectors, historical data logs of effluent amounts help with the inspection process. If a site has an issue in its readings, the ability to review historical records can help inspectors and operators narrow down and eliminate the problem.

For example, historical data allows the MCERTS inspector to:

See if the flume is correctly sized for the amount of flow that actually passes through the flume. An incorrectly sized flume could decrease the accuracy of the flow measurement.

See minimum/maximum flow amounts, which are based on the correct sizing of the flume.

Review average daily flows, which can assist inspectors in calculating the maximum uncertainty error.

Use these logs as a backup to any telemetry logging.

An integrated data logger can allow users to quickly and easily review the instrument’s historical performance.

WWTP operators can download logs to a computer using the device’s USB connection, and the device saves data logs even during power outages.

With more than 7,000 MCERTS-approved water sites in the U.K., inspectors are busy. A combination of experienced personnel, thorough inspection protocols and the application of reliable process instrumentation at a site make each day just that much easier.

Michael Cavanaugh is product manager, ultrasonics, in Siemens AG’s Industry Automation department. Visit siemens.com for more information.