Sand filter systems are crucial to the functionality of an offshore oil platform. The water and tanks or filters need to work properly and be cleaned regularly and correctly, and a process should be in place for valve or system failures. Manual sand filter systems can cause challenges for offshore oil platforms because many platforms cannot be in production without injection water.

“Lessons learned and best practices gleaned from this case study can apply to a variety of industrial water and wastewater processing systems when transitioning from manual to automated processes.”

Offshore oil platforms are held to a higher standard with more requirements and specifications, and automated processes provide many benefits. Manual processes are tedious and error prone, and they have a high level of operator variability. To overcome many of these challenges, most companies turn to control system integration and automation. Transitioning from manual to automated allows for greater visibility into the process, control and consistency in how the sand filter system is operated.

This article provides insights for transitioning from the labor-intensive and high-risk nature of manual systems to a modern automated control system. Although the focus here is integrating an automated sand filtration control system for an offshore oil platform, lessons learned and best practices gleaned from this case study can apply to a variety of industrial water and wastewater processing systems when transitioning from manual to automated processes.

Case study: Integrating an automated sand filtration control system for offshore oil platform

An offshore oil platform had many challenges with its existing manual sand filter system consisting of four tanks operating independently. The highest risk challenges included:

• Inconsistent operation from one shift to the next

• Poor visibility as to if and when the tanks had been properly backwashed and prepared for service

• Little to no alarming or alarm handling to divert to another filter in the event of valve failure

The existing manual sand filter system required the technicians to use push-buttons and outdated analog display devices on a large control panel to monitor and control the process. The manual sand filtration process was not integrated into a centralized system, which required constant operator interaction, device troubleshooting and training.

With the existing system, valves occasionally failed. With no alarming, the technicians were unaware until the pump faulted, due to pumping against a closed valve, causing downtime and stopped production. This situation can be prevented with an automated system by creating a sequence for valve alarming and diversion if a valve faults.

The process of backwashing a filter was also time-consuming in a manual system because operators needed to manually implement each step in the process by manually opening each valve. Naturally, operators become busy or distracted, and the backwash sequence would stall while waiting for an operator. By defining the sequence and integrating the devices into a control system, the process becomes automated. Thus, transitioning occurs automatically since operator input is not necessary.

The process also had no checks in place to ensure it met specifications for proper backwashing; the only timing mechanism was the operators themselves. The manual system kept no record of when the filter and tank had been cleaned and backwashed.

Project goals for the automated sand filtration control system

Integration of the sand filtration system from a manual process to an automated system was the oil platform’s overarching goal. However, it aimed to eventually integrate all of the processes for the oil platform into a single, centralized programmable logic controller (PLC) and human-machine interface (HMI) system. This ultimately increased overall system and process visibility, improved control, and enhanced operator or technician effectiveness while minimizing downtime.

“The automated sand filtration control system increased overall productivity and operator efficiency for the offshore oil company.”

Due to the limited availability of downtime and associated costs, the integration needed to be performed in a way that would minimize shutdowns. Therefore, during testing of the system, operators and technicians worked closely to lock the production path and avoid downtime.

Overcoming challenges with automation

To automate the system and reach the project goals, a new control panel to manage the system was designed and engineered. It included full electrical design, CAD drawings, I/O communications, design, I/O checkout and scaling, PLC and HMI development, procurement of the controls hardware and on-site commissioning of the system.

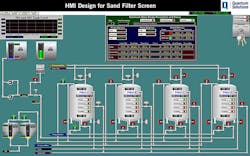

All of the individual devices were integrated into a centralized system. New HMI graphics were designed and implemented for much-improved visibility, control and alarming. A detailed sequence was engineered based on a full process review with the offshore oil platform’s experienced operators. This sequence provided the system functionality plan to control different modes of operations and path selection logic.

Programmed modes of operation

Four programmed modes were created to allow for improved performance, visibility and control over the filter process. These four modes included: In Service, Out of Service, Standby and Backwash. While the In Service, Out of Service and Standby modes are relatively simple to program and implement, the fourth mode, Backwash, requires a complicated sequence that follows a step-by-step procedure. For each mode to be initiated, the PLC system checks for permissive interlocks to ensure overall consistency, control, visibility and proper cleaning.

Custom HMI graphics, device visualization and navigation depicted on sand filter overview screen. Graphic courtesy of Quantum Solutions.

In Service — In Service mode indicates that the filter is in the production process and water is being passed through the tank/filter. This mode means that the process is running as it should. During the operation of In Service mode, the PLC system will continue to monitor for issues, manage alarms, and monitor output devices with input feedback.

Out of Service — Out of Service mode indicates that the filter is not available for production or taken down for service, repair or other maintenance. Once service or maintenance is complete, an operator puts the filter into Standby mode to begin production again.

Standby — Standby mode indicates that the filter is operational and available to go into one of the other three modes of operation. During Standby mode, all valves are closed and the operator has the ability to switch modes. In the event of a "path alarm" from the In Service filter, the system can automatically switch to a standby filter to avoid downtime.

Backwash — Backwash mode indicates that the tank/filter is in the cleaning process, and water is passed backward through the filter. Prior to starting this mode, the PLC will check to ensure that all permissive conditions are met. The automatic programming of the Backwash mode standardizes the backwashing process to the necessary specifications, decreases turnaround time, and minimizes operator interface while still allowing for operator control and the existing functionalities. Following the Backwash mode, the system automatically switches to Standby mode.

Alarms and alarm management

The manual sand filter system did not have an alarming system or an easy method to detect issues or malfunctions with the opening or closing of valves. With an automated sand filtration control system, alarms are monitored through all four modes. The alarm horn will sound and display an alarm message when there is an issue, but the automatic functioning will not change unless there is one of two critical alarms: inlet valve is open or outlet valve is open. When either of these critical alarms go off, the system will automatically pause the sequence and stop the supply pump to the tank. This will minimize errors and reduce downtime for maintenance.

Results of the automated sand filtration control system

The automated sand filtration control system increased overall productivity and operator efficiency for the offshore oil company. This was achieved through one-stop access to information on a single, automated control system. Operators no longer manually control every device; instead, processes are sequenced automatically to allow for increased visibility and consistency. Improved training for operators and technicians helps them to be more effective at minimizing errors.

Eric Casciaro is the CEO of Quantum Solutions, a national leader in automation and control systems with offices in St. Louis, Dallas and Chicago. He holds a Bachelor of Science degree in electrical engineering with a math minor from the University of Missouri. Casciaro’s project experience includes custom process batching applications and oil field automation to high-speed packaging, case packaging and warehouse line automation. Quantum Solutions is a member of the Control System Integrators Association (CSIA). For more information, visit the company profile at csiaexchange.com.