Ever wish you could take sludge out of your wastewater management equation? If you’re a facility manager dealing with traditional wastewater treatment systems, you’ve likely faced the headache that is sludge: the constant buildup, costly removal and continuous management.

Sludge isn’t just a byproduct — it’s a problem that compounds operational inefficiencies, drives up costs and makes compliance with environmental regulations harder every year.

But what if you could wave goodbye to sludge once and for all?

Sludge removal – a facility’s nightmare

Traditional wastewater treatment systems depend heavily on microorganisms to break down organic pollutants. These organisms feed on organic contaminants and multiply rapidly in aerated systems where oxygen is the provided. Over short periods of time, the microbes accumulate, forming what’s known as secondary sludge — tons of it. And suddenly, you’re faced with the ongoing issue: where to put it all?

In many facilities, sludge removal becomes a daily task, especially with aerobic systems. Anaerobic digesters, while efficient in producing energy from waste, still create substantial amounts of digestate — a biomass byproduct that also requires regular disposal. For industrial facilities in sectors like food and beverage manufacturing, the cost of sludge management can be a constant pain point.

The hidden impacts of sludge on industrial manufacturing facilities

Beyond the direct costs of removal and disposal, there are hidden impacts that ripple through the entire manufacturing process:

- Management time: Managing sludge isn’t a simple task. Facility managers spend significant time coordinating sludge removal, staying compliant with disposal regulations and responding to unforeseen complications like equipment failures or regulatory audits. This takes away valuable time from optimizing production or focusing on core business activities.

- Disruption of operations: Scheduling sludge cleanings often requires slowing down or even halting production to perform necessary maintenance. These disruptions can severely affect production schedules, lead to delays in product delivery and add operational costs.

- Hauling and disposal risks: Sludge hauling is risky and can expose a facility to environmental fines and safety hazards from spills or accidents. Additionally, hauling contributes to a facility’s Scope 3 emissions — those indirect greenhouse gas emissions tied to operations but outside a facility’s direct control. This adds to a company’s environmental footprint and affects sustainability goals.

- Regulatory burden: Land application, once a common disposal method, is facing increasing restrictions due to concerns about nitrates, heavy metals and other contaminants affecting soil and water quality. Staying compliant requires proper disposal methods, ongoing testing, documentation and reporting, further straining facility resources.

The future of wastewater treatment is sludge-free

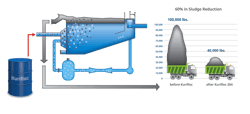

As wastewater treatment systems evolve, sludge doesn’t have to be an inevitable byproduct. Aquacycl, for instance, offers a future where sludge management is simplified, operations are streamlined, and costs are reduced — all while keeping the environment safe.