Microbes have been used for hundreds of years to treat wastewater for organic compounds and nutrients. In recent years, selenium removal has been demonstrated as another constituent for which biological treatment is effective.

Removal of selenium from wastewater prior to discharge to lakes and rivers is of growing interest for the protection of aquatic life. Agricultural runoff, coal-fired power plant and mine-impacted wastewaters, along with other industrial effluent streams, are being treated to ever more stringent regulatory limits by federal, state and provincial environmental authorities.

In response to this, facilities are using specialized microorganisms as part of treatment systems to successfully remove selenium to meet the challenge. But before the industry tries to take more action against selenium, regulatory limits for the discharge of selenium need to be brought into perspective. Water quality-based regulatory limits in parts of North America are less than 5 micrograms per liter (µg/l) based on the protection of aquatic life. Compare this with the U.S. Environmental Protection Agency’s standard for drinking water of no more than 50 µg/l. Even more interesting is that the US Food and Drug Administration mandates a minimum selenium concentration in infant formula based on calories, which translates to at least 13 µg/l.

With these numbers in mind, it should be recognized that selenium, much like other constituents of concern — e.g., boron, chrome or vanadium — is an essential nutrient for plant and animal health. Even drinking water can fall into this category. Too little, and organisms will not thrive, while too much may be toxic.

How is selenium treated?

As facilities look to treat wastewater for selenium, it is important to understand the forms selenium may be in, the mechanisms of treatment and the potential need to also treat for other constituents. All these variables factor into the development of the most economical design possible, while ensuring safety, environmental compliance and operational reliability.

Oxidized forms of selenium, selenite and selenate, are typically the most prevalent forms in many impacted wastewaters, with selenate, the fully oxidized form, being the most difficult to treat. In fact, traditional physical/chemical wastewater treatment processes are challenged to reduce selenate concentrations to any appreciable level due to their high solubility.

Given the difficulty with these processes, many facilities have turned to biological-based treatment, which transforms the selenium from a soluble and toxic form to a precipitate that can be safely handled and disposed.

During biological-based treatment, microbial respiration is performed in a controlled environment to first deplete nitrate, a more energetic electron acceptor, followed by bacteria respiring selenate to selenite. The process continues through selenite to form insoluble elemental selenium at the outer membranes of the microbes. The elemental selenium is in the form of amorphous nano-spheres, which have potential uses in the electronics and photovoltaic industries if economical methods of harvesting can be developed.

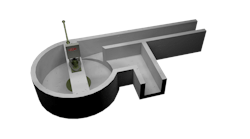

Several approaches have been taken to utilize bioreactors for selenium removal, with a common element being the use of granulated activated carbon (GAC) as a structural matrix for the microbes to attach themselves to. GAC not only provides a structure, but the extremely large surface area-to-volume ratio allows for abundant attachment sites. Early installations utilized anthracite-based GAC based on the belief that it would be more resistant to abrasion during the back wash process. It was found, however, that several metals were released in the form of fine particulates upon initial placement and subsequent maintenance events. Recent installations have utilized coconut-based GAC to mitigate the release of inorganic fines without issue.

Up flow, down flow, fluidized, expanded and packed bed variations are in use, each having their own advantages. A common feature of these bioreactor configurations is that while most are initially inoculated with a culture of naturally occurring, selenium-reducing bacteria, commonly pseudomonas strains. Over time, the biomass evolves and adapts to the prevailing water chemistry and conditions. An excursion in influent water chemistry that may disrupt bioreactor performance is rapidly recovered from once corrected.

These bioreactors have similar nutrient requirements as the more traditional suspended growth units found in municipal applications. A carbon source (electron donor), nitrogen and phosphorous are all needed to maintain a balanced diet for the biomass. The carbon source is added to the system based on a targeted oxidation reduction potential (ORP). The negative ORP set points ensure that the microbes are driving the selenium reducing reactions while minimizing the formation of other undesirable compounds in the matrix — hydrogen sulfide for example. The reductive conditions also result in denitrification of the water, causing the release of nitrogen and carbon dioxide gasses in the form of effervescence.

In practice

There is a lot of complexity for industrial wastewater treatment facilities as they look to comply with changing regulations. Stantec is working on several projects for the electric power utility industry where bioreactors are one component of the multi-step treatment processes. The EPA in 2015 identified biological reduction of selenium as the best available technology economically achievable for treatment of flue gas desulfurization wastewaters. Since then, studies, pilots and full-scale designs have occurred for systems ranging from 100 gallons per minute up to 4,400 gallons per minute.

Making these designs even more challenging is the decline in coal-fired power generation. Due to a reduction in the use of coal, power plants that once generated a relatively consistent flow of wastewater to be treated now swing widely and at times are idle for months at a time.

Fortunately, this has not been an issue for the bioreactors. Innovative system design and operating practices have allowed some reactors to be idle for months at a time and performing as designed within a day of restart.

Biological treatment for the reliable removal of selenium is a proven technology in many industries, with over two dozen systems installed and a dozen more under construction. Since first introduced, the systems have advanced to produce safe, environmentally compliant, reliable and cost-effective performance.

With ongoing changes in industries and the environment, complying with evolving treatment requirements can be challenging, especially with a constituent as complex as selenium. The key to successful treatment is in a robust design and an informed approach without “debugging” the system.

Bill Kennedy is senior principal and regional discipline leader for industrial water at Stantec.