Improving the Spread

Water treatment system helps margarine manufacturer reduce water consumption, costs

By Bryan Brister

New regulations and an awareness of the need for environmental responsibility have helped fuel the push for innovative water treatment solutions in a variety of industries. As a result, water treatment technologies such as electrodialysis reversal (EDR), ion exchange and membrane capacitive deionization have rapidly gained acceptance in the once-conservative commercial and industrial water treatment market. They are paving the way for water consultants and distributors to add more sustainable options to their product catalogs.

On site at Unilever in Pratau, Germany, for the CapDI IS2 System installation.

Because of the extensive amount of water consumed by certain sectors, businesses are taking every opportunity to reduce the amount of water used and are now looking for options that allow them to do just that. Cooling towers, specifically, are among the highest water consumers and also have some of the worst scaling and corrosion issues. When the equipment is not maintained properly, an even greater amount of water can be wasted.

One customer in particular was looking for an easy-to-use technology that required little maintenance and also had the ability to maintain a consistent quality output through any water quality spikes in turbidity. It decided to do away with its current water treatment plan in place of a newer, less traditional option.

A look into the internal panel box of the CapDI IS2 System, installed at the Unilever plant in Pratau, Germany.

Margarine Manufacturer Faces High Costs

Unilever, a margarine manufacturer located in Pratau, Germany, was using a large amount of water during its manufacturing process. The plant is located in a part of Germany known for its extraordinary water costs, which added urgency to finding a water treatment solution for its cooling towers.

In order to lower its water consumption, Unilever evaluated various water treatment solutions, including reverse osmosis (RO) and membrane capacitive deionization. Ultimately, the manufacturer determined that RO was not an efficient water treatment solution for its needs for a couple of reasons. First, RO produces ultrapure water as it removes all salt and total dissolved solids (TDS), which can have a negative effect on a cooling tower and steel pipes. In fact, it’s very common for water treated with RO to actually corrode steel pipes because the water can remove the iron from the pipes and neutralize itself.

Second, water with a very low salt concentration is considered unbalanced and will naturally attempt to take in salts from other sources to balance itself out. This type of corrosion eats away at valuable equipment and causes structural damage to cooling operations.

And finally, a typical RO system will be accompanied by a water softener to place soft salts back into the water stream where the majority of the hard salts have been removed. This piece of the process unfortunately also causes issues within cooling towers as it produces a higher concentration of salt that is used within the cooling loop. When there is evaporation, that salt is left behind and causes unnecessary corrosion and scale, often leading to more water consumed.

Membrane Capacitive Deionization

Unilever opted for Voltea’s Membrane Capacitive Deionization (CapDI©), a salt-free water purification technology wherein salt ions and TDS are removed via an electrical current. In a simple two-step process, positive ions are attracted to the negative electrodes while negative ions are attracted to the positive electrodes to create a stream of pure water flowing out of the system. When the ions are fully saturated, they flip polarity, where these ions are then discharged.

The sustainable and environmentally responsible feature of this process is that there are never any soft salts added to the system to replace the hard salts that were removed. This allows the same salinity and mineral level that was in the original water source to be discharged without additional, higher salt levels. Traditional water softeners, where hard salts are replaced by soft salts, have been banned in some municipalities, especially those struck by drought or those that have made environmental concerns a priority.

Customizable Technology

Membrane capacitive deionization is tunable, which means the user can customize the desired level of salt or TDS removal based on the application. In a traditional RO process, all of the salts and TDS are removed, which then requires a water softener to re-salt the water back to the original desired level of salinity. This pressurized process not only requires a higher level of energy but results in a higher level of salts being discharged back into the environment.

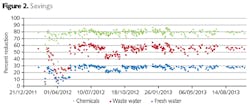

The tunability feature removes unnecessary extra steps in the treatment process while eliminating a high concentration of salt in the discharge water. Membrane Capacitive Deionization also allows the reduction of chemicals, water consumption and wastewater for a quantitative analysis of savings.

Quantifiable Results

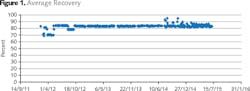

After a year and a half of operational data at the Unilever facility, the CapDI System produced notable results, including:

• A 26 percent reduction in fresh water consumption

• More than 50 percent decrease in wastewater

• A 78 percent reduction in chemical consumption

This example illustrated that, for Unilever, membrane capacitive deionization proved to be a more environmentally responsible option for water purification for cooling towers than traditional water treatment systems such as RO.

It also yielded significant cost reductions in water and chemical costs, saving about $14,000 with an ROI of just over six months of operation. This data stayed consistent through this operational period while the water recovery of the CapDI System maintained an average of 83 percent. IWW

@bio:About the Author: Bryan Brister is CEO of water technology company Voltea. Prior to joining Voltea in 2014, Brister spent eight years with General Electric and was as a founding member of Seven Seas Water. Brister holds a bachelor’s degree in biochemistry and a Ph.D. in polymer science and engineering.

Circle No. 153 on Reader Service Card