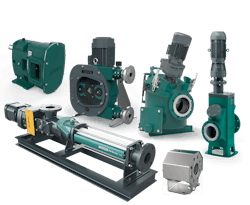

NETZSCH to showcase fluid handling solutions for wastewater industry at WEFTEC

NETZSCH Pumps USA, a global leader in complex fluid handling solutions, will showcase its advanced, field-proven equipment for demanding wastewater applications at WEFTEC 2024, taking place Oct. 7–9 in New Orleans. Visit booth 5929 to see the PERIPRO® Peristaltic Hose Pump, the enhanced TORNADO® T1 Rotary Lobe Pump, and the N.Mac® Twin Shaft Grinder, and discover NETZSCH's full range of innovative and reliable fluid handling solutions for the wastewater industry.

The PERIPRO Peristaltic Pump is the latest generation of peristaltic hose pumps, designed for heavy-duty applications with the ability to handle both low and large flow rates across a wide range of pressures. Ideal for complex fluids, including abrasive, corrosive, viscous, and delicate products, the PERIPRO pump features large, easy-to-maintain rollers that extend service life. Its robust design offers up to 30% energy savings and requires 90% less lubricant compared to other hose pumps using shoe technology. Enhanced leak detection further ensures reliability and longevity, making it a powerful and durable addition to the NETZSCH pump portfolio.

The TORNADO T1 Generation F Rotary Lobe Pump is an extremely versatile solution for wastewater treatment applications requiring high flow at low to medium pressures in a small compact package in just about any orientation and installation. Capable of handling various viscosities, solids, temperatures, abrasions, and corrosive environments, this pump offers exceptional versatility, longevity, and dry-run capabilities. The Full Service-in-Place (FSIP®) process side allows for easy maintenance, while the NETZSCH Gearbox Security System (GSS) protects critical components, reducing the total cost of ownership. The new Generation F series offers up to 25% more efficiency, with enhanced flange sealing, one-piece housing, and advanced materials, ensuring long-term, reliable performance.

The N.Mac Twin Shaft Grinder is ideal for wastewater treatment, biogas and biomass plants, food, animal processing, and other waste and industrial applications. Featuring cartridge cutting knives for quick and simple replacement and servicing, the N.Mac® offers quenched lubricated mechanical seals for dry running capability. The mechanical seal cartridge design— a leak free combination of mechanical seal and bearing cartridges— enables quick and simple replacement and servicing. Available in both channel and inline (flanged) housing construction, the N.Mac® can be installed into effluent channels or upstream from a pump.

To learn more about how NETZSCH can support your complex fluid handling needs, visit booth #5929 at WEFTEC or https://pumps-systems.netzsch.com/en-US.