Bio-based additives are solving performance challenges in heavy-duty water treatment formulations

Bio-based products are becoming an essential partner in the fight to reduce the impact of industrial activity on climate and the environment. However, there is still a misconception about the performance of these technologies. It is proven that bio-based materials can perform equally or better than technologies manufactured with traditional processes or petroleum-based raw materials. This article examines how a novel chemoenzymatic process can address the challenge of finding materials and processes that are friendly to the environment and cost-effective without compromising performance in water treatment applications. This unique process allows the manufacturing of building blocks that will support the development of effective cooling water formulations with a better environmental profile.

Introduction

Solugen has developed and is currently scaling up a differentiated chemoenzymatic technology platform. This process uses highly efficient enzymes and novel metal catalysts to produce organic acid products and hydrogen peroxide from sustainable and domestically produced bio-based feedstocks. These building blocks have been designed to satisfy the need for greener technologies with improved performance.

The purpose of this article is to demonstrate how the use of a new class of bio-based chemicals (a hydrophilic carboxylic acid (HCA) and hydrophilic dicarboxylic acid (HDA)) can address technical challenges such as the effects of trace metal ions (Fe3+ and Cu2+) in the control of CaPO4 scale, copper-induced pitting and corrosion while enabling low phosphorus water treatment programs and formula optimization.

Environmental profile

Although the environmental profile of water treatment products has improved through the decades, today’s common water treatment products are not environmentally benign.1

While many of these products are addressing the need to control corrosion and scale formation, they typically include phosphorous, nitrogen or heavy metals such as zinc, or molybdenum. Phosphorus-based products can lead to eutrophication that accelerates the growth of algae and other plants that reduce the quality of the water for local communities, municipalities and recreational use. In the United States, eutrophication is estimated to lead to $2 billion dollars of damage annually.2

Phosphates, azoles and zinc contribute to harmful eutrophication or aquatic toxicity when discharged to the aquatic environment. The molecules manufactured by Solugen’s BioforgeTM, known as the AcquaCoreTM series, contains only carbon hydrogen and oxygen and comprises no residual manufacturing impurities. This molecule comes in primarily two different variations, HCA and HDA.

The HCA and HDA molecules do not contribute nitrogen or phosphorous to the environment and reduce the need for triazoles, phosphonates and polyacrylates in a water treatment formulation. Additionally, Solugen’s HCA and HDA both have a favorable Life Cycle Analysis3 for greenhouse gas emissions in comparison to conventional chemical processes. For every ton of Solugen’s AcquaCore product that is used in replacement of hydroxyethylidene diphosphonic acid (HEDP), more than 3 tons of greenhouse gas equivalents are reduced.3

HCA and HDA are effective technologies to control metal ions

It is well-established in previous literature that soluble ions can impact the performance of water treatment programs. Iron, particularly Fe+3, reduces the effectiveness of calcium phosphate inhibitors.5 The presence of soluble Cu+2 greatly increases corrosion of iron, aluminum and galvanized steel through reductive plating and galvanic corrosion.6 Additionally, copper promotes the formation of soluble or insoluble compounds with the benzotriazoles. When they are complexed, the benzotriazoles are less able to function as corrosion inhibitors. Since copper ions are well-known oxidation catalysts, this complex formation is also likely to contribute to the oxidative decomposition of the soluble azoles.

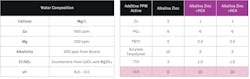

When adding HCA and HDA to a formulation, they form stable complexes with many of the metal cations commonly found in cooling water systems. Table 1 shows some of the known stability constants of these complexes. The high affinity for Cu+2 and Fe+3 is particularly relevant because of the performance issues associated with those ions.

An example of the efficacy of the AcquaCore series is in the management of copper-induced pitting in carbon steel in cooling towers.

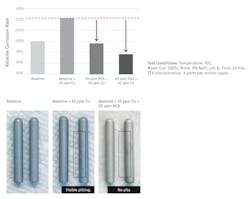

It is known that cooling tower water is extremely corrosive to carbon steel equipment and soluble copper leads to a higher carbon steel corrosion. The corrosivity depends on the process conditions, outside environment and the water treatment. HCA exhibits corrosion inhibition properties on multiple metals. It forms stable complexes with metal ions, which are used in corrosion inhibitor formulations. It also stabilizes harmful trace ions contained in source water or due to corrosion products. In a study conducted by Solugen, the addition of HCA significantly impedes copper-induced corrosion of carbon steel (Figure 2).

Benefits of using HCA and HDA in heavy-duty water treatment formulations

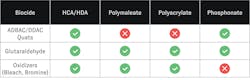

HCA and HDA chemistries provide a solution that allows the industry to develop differentiated water treatment formulations with improved performance and environmental profile due to their inherent corrosion inhibition properties, ability to chelate harmful metal ions and compatibility with quaternary amine and oxidizing biocides.

Adding Solugen’s technologies to copper or yellow metal corrosion inhibitor formulations allows the reduction of benzotriazole and tolyltriazole (TTA). This solves the main issues when working with triazoles: 1) the triazole family of intermediates are known to be reactive with halogenated biocides and can be deactivated via precipitation with soluble copper, and 2) the environmental concerns due to their aquatic toxicity.

In the next section, are examples of how the addition of Solugen’s technologies in heavy-duty formulations such as alkaline zinc and a stabilized phosphate will reduce the amount of harmful chemistries used while performing equal to or better than the traditional formulation. Please note that the following tests were performed at 40˚C, using a C1018 electrode, using constant air sparging and a stir bar set at 200 revolutions per minute (RPM).

Alkaline zinc formulations

Alkaline zinc products are a popular choice to treat open recirculating systems when severe corrosion conditions exist. In this study, a typical alkaline zinc formulation is compared against a modified formula where the levels of zinc, phosphate, scale inhibitors and azole were reduced, and HCA was added at different concentrations.

Figure 3 demonstrates the ability of HCA to reduce the need for zinc, phosphate, azole and scale inhibitors in the formulation. When adding 10 ppm of HCA the level of corrosion inhibition was equivalent. In comparison, when the concentration of HCA was increased to 20 ppm the study showed an improvement in corrosion performance.

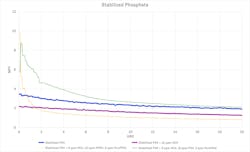

Stabilized phosphate formulations

Stabilized phosphate products were introduced as chromate replacements in the late 1970s and have become widely accepted in the heavy industrial market where pH control is the norm and severely corrosive conditions are observed. The following results illustrate how HCA can play a role in this type of water treatment formulation.

The results below indicate that the corrosion inhibition performance of stabilized phosphate programs can be significantly improved through the addition of 5 ppm of HCA. The data also suggests that the phosphate dosage can be reduced by half while maintaining a similar level of corrosion inhibition.

Conclusion

Solugen’s innovative non-toxic AcquaCore series provides unique functionality in water treatment programs by mitigating the effects of trace ferric iron and copper. The benefits of adding HCA and HDA in water treatment formulations are:

- Mitigation of galvanic corrosion due to copper plating on susceptible metals.

- Enhancement of the activity of azoles allowing reduced azole usage.

- Improvement of copper inhibitive properties of the azoles in the presence of halogen biocides.

- Functionality as an ingredient in non-P and non-P-nonmetal formulations.

- Improved performance and reduced phosphorous content in current water treatment programs.

- Formula optimization.

- Domestically manufactured and world-scale availability.

Solugen’s technologies present scalable, efficient and sustainable solutions to problems with today’s water treatment actives and enables effective greener products for tomorrow.

References

- Rey, Susan. “Carbon Steel Corrosion Control in the Past Twenty Years and in the New Millennium” Paper presented at the Association of Water Technology Conference 2000.

- Gledhill, William E, and Tom C J Feijtel. “Environmental Properties and Safety Assessment of Organic Phosphonates Used for Detergent and Water Treatment Applications.” Essay in The Handbook of Environmental Chemistry 3, edited by Hutzinger, Fed. Vol. 3. Springer-Verlag Berlin Heidelberg, 1992.

- Lifecycle Analysis, Life Cycle Associates, 2020.

- Smith, Robert M., and Arthur Earl Martell. Critical Stability Constants. New York: Plenum Press, 1989.

- Shen, Dong, Shcolnik, David, Perkins, Randall, Taylor, Grahame, and Mike Brown. “Evaluation of Scale Inhibitors in Marcellus High-Iron Waters” Essay in Oil and Gas Facilities, Society of Petroleum Engineers, 2012.

- Fox, Katherine, Tate, Carol, Treweek, Gordon, Trussell, R. Rhodes, Bowers, A. Eugene, McDuire, Michael, and Dale Newkirk. Copper-Induced Corrosion of Galvanized Steel Pipe. United States Environmental Protection Agency, 1989.

Frederyk Ngantung is the vice president of product at Solugen, where he leads a multidisciplinary team to develop carbon-negative products to solve unmet needs in markets such as water treatment, agriculture, food, and beverage, among others. With over 15 years of experience including stints at a corporate venture capital firm and three bio-based chemical startups, Ngantung has developed deep expertise around bringing bio-based products to market.

LoongYi Tan is the director of product at Solugen, where he commercializes Solugen’s bio-based water treatment products to address the customer’s need for high-performing and environmentally friendly cooling solutions.

Jun Su An is the director of product at Solugen. An has a wealth of experience and knowledge in developing new, novel and optimized solutions in various industries including the industrial water treatment sector. His expertise includes chemical engineering, manufacturing, applications/formulations and product development.

Chris Arceo is the senior scientist at Solugen. Arceo has been working as a chemist for over 20 years, with over 10 years of experience in corrosion formulations. His expertise includes sweet or sour corrosion and analyzing metal samples post-analysis.

Carolina Ramirez is the head of product marketing of Solugen. She has a wealth of experience with 15 years in the chemical industry.

![Table 1: Stability constants of HCA and HDA versus other chelating agents[4]. Table 1: Stability constants of HCA and HDA versus other chelating agents[4].](https://img.watertechonline.com/files/base/ebm/wto/image/2021/11/Table_1.619e6734b6e64.png?auto=format,compress&fit=max&q=45&w=250&width=250)