From production to cleaning and sanitation, meat operations produce wastewater from many sources that typically contain high levels of contaminants, suspended solids, organic compounds, ammonia compounds and fats, oils and grease (FOG). These compounds and contaminants can cause significant damage to the environment and public health if not properly treated.

Given all these factors, developing a safe, effective solution to treat wastewater — whether to meet industry regulations or corporate environmental goals — is critical. At the same time, however, it is not always a clear-cut process, requiring the right combination of physical, chemical and biological processes rather than a one-size-fits-all solution.

To help select the best wastewater treatment strategy for meat processing application, this article provides a helpful overview of the types of contaminants you will encounter. It will also explore integrated wastewater technologies that not only effectively remove the contaminants, but also offer cost, energy and performance advantages.

The role of water in meat applications

Meat processing facilities require high volumes of water for many applications. For example, meat processing plants use water to clean livestock, cool processed meat and produce brines and marinades. Facilities also use water to clean and sanitize floors and equipment, as well as to transport waste.

The wastewater generated from all these processes must be thoroughly treated to comply with regulations, protect the environment and safeguard public health. Many government bodies, for example, seek to limit the amount of pollutants, including biochemical oxygen demand (BOD), nitrogen and phosphorus, that are discharged into bodies of water, thus preventing contaminants from harming aquatic life and degrading water quality. Treating wastewater from these applications also prevents the spread of harmful pathogens like E. coli, Salmonella and Listeria.

It is important to be familiar with the specific contaminants present within meat processing wastewater, and the technologies that offer solutions to these challenges, in order to specify the optimal treatment solution. Here are some treatment methods:

Physical separation methods

Removing FOG and total suspended solids (TSS) from wastewater can be resolved using dissolved air flotation (DAF) technology, which removes non-soluble organics by dissolving pressurized air into water and forming tiny microbubbles. As these bubbles enter the flotation zone located within the DAF system, contaminant particles attach to the bubbles, lowering the particle density and causing the FOG and other non-soluble organics to separate from the wastewater and rise to the surface. The top surface layer of separated contaminants is then skimmed and collected into a sludge hopper.

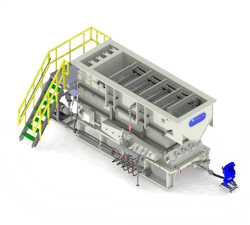

While most meat processing operations require this treatment to meet regulations, not all DAF systems are created equal. The best ones, such as the World Water Works (WWW) Ideal DAF, incorporate a compact design, low operational chemistry and energy costs, and high removal efficiency. The system features a cross-flow design that facilitates lower water velocities and better solid separation. To optimize the treatment process, the influent header includes multiple injection points, allowing the introduction of whitewater — a highly saturated pressurized stream of air and DAF influent that includes a polymer flocculant. The Ideal DAF features a cone-bottom design for easy settled sludge removal.

The Ideal DAF can also withstand demanding environments thanks to its heavy-duty yet lightweight polypropylene (PP) construction. In addition to extending the system’s service life, this PP construction offers excellent corrosion, pH and temperature resistance, as well as total dissolved solids (TDS) and saltwater tolerance.

Addressing biological contaminants

In addition to FOG and non-soluble organic compounds, meat processing wastewater contains high levels of biological contaminations, such as BOD, ammonia-nitrogen (NH3-N) and phosphorus. One common biological treatment method is the activated sludge process, which involves treating wastewater with bacteria.

These microorganisms promote their metabolism and growth as they degrade the organic material. As they grow, they consume organic matter, nutrients and other contaminants within the wastewater, producing carbon dioxide, water and biomass. This digested wastewater then gravity flows to a secondary clarifier for sedimentation of the bacteria. The bacteria returns to the head of the aeration tank while the clarified water discharges from the plant. Part of the return sludge, known as waste activated sludge (WAS), is wasted and disposed of.

Another biological treatment method uses a moving bed biofilm reactor (MBBR), which is a fixed-film process that addresses BOD removal, as well as nitrification and denitrification. This method relies on specially designed bio-media within the MBBR tank that enables bacterial growth. The media’s large, protected surface area provides enough space for biofilms to grow. These biofilms digest the organic matter in the wastewater and convert soluble material into biomass that can be removed downstream. Near the top of the tank, a stainless-steel sieve allows water to exit the reactor while preventing the bio-media from escaping.

Phosphorous removal treatments

Contaminants like phosphorus and other nutrients must be removed before discharging the wastewater into the environment — a challenge that physical-chemical solutions can address. Adding coagulants and flocculants to the wastewater, for example, can remove suspended solids, while processes like ferric chloride and polyaluminum chloride (PAC) precipitation can remove the phosphorus.

How to achieve success

By implementing effective wastewater treatment methods, meat processing plants can comply with emerging regulations, meet business targets, reduce treatment costs and minimize environmental impact. For additional assistance, it pays to work with wastewater treatment professionals with a longstanding history and track record of proven success, enabling you to navigate industry challenges and deploy an optimal solution.