In order to keep reliability high, various condition monitoring/diagnostic tools should be employed for water pumps. The vibration, the wear, the flow, the pressure and the temperature are the important condition monitoring parameters/techniques to predict the health of any rotating machinery. The common deterioration/degradation effects in a water pump are usually the vibration, the noise, the corrosion, the erosion, the oil debris, the pressure variation, the flow reduction and the speed change. The success of a water pump monitoring system does not only depend on the perfection of the monitoring hardware/software themselves, but it is determined by a correct monitoring integration with the maintenance when both can be considered as one.

The water pump condition monitoring/maintenance programs are designed with a special focus on critical areas, such as bearings and impellers, to avoid frequent shutdowns, reliability issues, safety problems or hazardous situations. The operation philosophy is also important for the monitoring of the water pumps. Sometimes, the time-based maintenance approach is selected. In this way, the operator may operate water pumps without any shutdown for a certain period of time and then overhaul them on a regular basis.

It is an old-fashion method that results in many issues and problems. The condition-based maintenance method is always preferred. It is much better to run every pump until it shows some sign of distress before an overhaul. The result is doing a lot less overhauls. This type of approach requires more monitoring and routine inspection to avoid a catastrophic failure.

To cut unnecessary maintenance costs, the key decision is not to shutdown a water pump for overhaul without a scientific reason for doing so.

Advanced monitoring

The condition monitoring is the observation and the analysis of observable parameters to estimate the internal conditions of a water pump, particularly to identify expected run-length and predict any likely failure. The online condition monitoring methods, such as the vibration monitoring, the oil analysis, the wear debris analysis, the performance monitoring and the temperature monitoring, are extensively used for the water pumps.

Oil/wear analysis

The "Spectrometric Oil Analysis" (SOA) method could be used, which measures and predetermines metals and their quantity in the oil, with the intention of identifying an excessive wear. As data is gathered, a wear trend is compiled and compared against a statistical baseline. More benefits could be obtained through the addition of the "Magnetic Plug Analysis" to the "SOA," particularly for a small/medium water pump, which are equipped with the rolling-element bearings.

Performance monitoring

The simplest form of the performance monitoring involves the trending of key variables (for example, the pressures, the pressure ratios, the bearing temperatures, the speed, the water pump consumed power and others) and comparing them with a baseline which has been developed. The trends on the water pump power consumptions, the water pump efficiencies and the water pump degradations are always important. The performance analysis can provide a deep insight into water pump component performances, revealing gradual degradation mechanisms and abrupt faults.

Vibration monitoring

The water pump vibration monitoring is usually based on the vibrational sensor measurements and the comparison to an advanced dynamic model to identify the problem, which could be an early indication of a possible failure. The pump dynamic model should take into account accurately all main components and the flexibilities of the pump. The pump rotor assembly, all rotor assembly supports (including bearings), the pump casing and all external supports should be properly modeled. The dynamic model should respect all nonlinear effects and all elements particularly accurate models for all parts between rotating and static assemblies of a water pump (for example, the bearings, the bearing supports, the sealing and others). Usually the dynamic model is specific to the water pump type/model.

For many water pumps, particularly small/medium pumps, which use rolling-element bearings, considerable flexibilities (of casing, support and bearing) make the dynamic model more complex. A considerable casing/support flexibility could be the reason for the bound flexural whirling vibrations. More accurate/realistic experimental vibration data describing the dynamic properties of some complex elements of a pump, such as the casing and the supports, should be used if there is any doubt in the pump theoretical model. Using detailed/deep knowledge of the vibration analysis, one can accurately predict the structural/mechanical/bearing conditions of a water pump.

Rolling element bearings

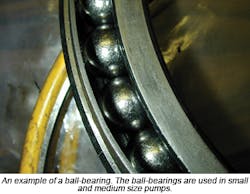

Small/medium water pumps generally use rolling-element bearings. These pumps should be modeled as rotor assemblies supported by the nonlinear bearings, installed on the flexible bearing supports. The dynamic behavior is completely "nonlinear."

The bearing stiffness can vary with the rotating speed, the applied-preload and transmitted loads (for example, because of the unbalance). The rolling-element bearings should usually be modeled in five degrees of freedom and the nonlinear stiffness characteristics of the bearings should be completely described as functions of the combined loads and the rotating speed.

The results of different studies have shown that the nonlinear stiffness characteristics of rolling-element bearings significantly influence the pump dynamic behaviors. Generally, large numbers of parameters, including the accurate bearing geometry details, detailed element properties, the stiffness distribution of the rotating shaft assembly, the bearing stiffness, the centrifugal forces, the gyroscopic moments, the raceway (inner-raceway and outer-raceway) load-deflection factors and different material effects can influence the dynamic behavior of a pump rotor-bearing system.

The nonlinear model is essential for any small/medium water pump using rolling-element bearings. In a case study for a small water pump with ball-bearings, a detailed comparison showed there are great differences between an accurate nonlinear model and a model based on linear assumptions. The discrepancies of the first and the second critical speeds of two models are 11 percent and 8 percent, respectively.

In other words, linear assumptions can easily result in missed resonances, operational problems and even serious damage. The effect of the rotating speed on the bearing stiffness is significant and the stiffness characteristic is "anisotropic." The whirl orbits near the critical speeds become quite elliptical (because of anisotropic effects) as the unbalance magnitude increases.

This reflects that the bearing stiffness characteristics become anisotropic due to the loads transmitted from the rotating shaft and its support. The whirl orbit results from an accurate model at speeds with a fair distance to critical speeds (the speeds outside the critical speed margins) are nearly circular. In other words, the anisotropic effects of the bearings could be small for the speeds not close to the critical speeds.

Journal bearings

Critical issues related to the journal bearings of large water pumps (often above 1 MW power rating) are:

- A proper bearing design

- A sufficient loading capacity of the bearing

- A proper lubrication system (sufficient flow/pressure of the clean, cooled lubrication oil)

The contaminated lubrication oil could be the root cause for many failures and operational problems in large water pumps. Generally, a very robust design, a high-strength bearing structure and a high-grade Babbitt material (for the journal bearings) should be used.

Different parameters, such as the oil film details, the extreme pressures of the lubrication and the minimum clearance at the bearing, should carefully be evaluated against the speed. The lubrication flow, the lubrication pressure and the lubrication temperature require a proper monitoring. The bearing metal temperatures are also important.

The journal bearings of large water pumps can present a nonlinear behavior, but they are offering probably a less nonlinearity compared to the rolling-element bearings in the small/medium pumps. Many simulations have demonstrated the linear rotordynamics cannot account for a proper vibration prediction during all operation modes.

For example, in a relatively high unbalance, as can be occurred during a pump operation (such as a marginal unbalance close to alarm or trip levels), the linear assumptions are clearly insufficient and a proper nonlinear model is required for accurate simulations.

Amin Almasi is a lead rotating equipment engineer at WorleyParsons Services Pty Ltd, Brisbane, Australia. He previously worked at Tecnicas Reunidas (Madrid, Spain) and Fluor. He holds chartered professional engineer license from Engineers Australia (MIEAust CPEng – Mechanical), chartered engineer certificate from IMechE (CEng MIMechE), RPEQ (Registered Professional Engineer in Queensland) and he also holds MS and BS in mechanical engineering. He has authored more than 60 papers and articles dealing with rotating machines.

Figures:

Figure 1 – An example of a ball-bearing. The ball-bearings are used in small and medium size pumps.

Figure 2 – An example of a thrust (axial) roller-bearing.

Figure 3 – An example of a sensor for the condition monitoring.