The assumption that industrial filtration is a one-stop shop allowing businesses to satisfy their total filtration needs with a single piece of equipment is incorrect. Most industrial water applications require a symphony of filtration steps to achieve the desired result, whether that result is total biochemical oxygen demand (BOD) reduction, total suspended solids (TSS) removal, clarification or simply nozzle protection.

Automatic, self-cleaning filter

Industrial users require filtration solutions for process water and wastewater. On the process water side, it is important to filter their high value product and, in some cases, recover solids from those products. To achieve this, they routinely use bags, cartridges and centrifuges. On the wastewater side, dewatering and filtering out impurities to meet regulatory standards are important. By concentrating these solids, businesses experience lower disposal fees.

Primary filters such as rotary drums can take an initial high pass at large solids removal, but what happens when numerous particles pass through the drum filter and onto a secondary filter, such as a dissolved air flotation or clarifier system? The entire system suffers from an overload of solids and expensive cautionary measures must be taken to ensure continuous flow. This is when an automatic, self-cleaning filter becomes an integral part of the total filtration process in both bulk solids removal by concentration and filtration separation.

Initial solids isolation is a crucial step toward making sure downstream efforts are not overextended to compensate for the high loading of solids that remain in the system. Chemical additives are a costly and sometimes unwanted solution, and centrifuges are expensive and require frequent maintenance.

Other traditional solutions such as bags, cartridges and media filters result in equipment redundancy, large footprints, expensive personnel resources and an unfavorable environmental impact. Such problems can be remedied by installing equipment between the primary filter and the final filter. This market segment is the domain of automatic, self-cleaning filters.

In the past, traditional automatic, self-cleaning filters cannot handle high solids loading or fats, oils and greases for an extended period without blinding off. New technologies combat these process challenges by immediately isolating high solids in a concentration chamber, which allows flow rates to be maintained during the filtration process.

Benefits for food and beverage producers

The demands for innovation from industrial water processors have resulted in unexpected benefits for certain business sectors. Food and beverage processors now find that advancements in automatic-filtration technology come with industry-specific solutions.

A food and beverage producer may consider the process to be more separation than filtration. Recovered solids are not necessarily waste product. In some cases, these solids may become a nutrient-rich byproduct that can be sold to create an ancillary revenue stream. The process must also protect the product itself. The heat and pressure of centrifuge filtration systems may adversely affect flavor. Waste and efficiency are concerns for any industrial process, but when the product is wine or juice, product loss can also become a significant operating expense.

Industrial process water serves many different markets, each with its own set of challenges. In the California Central Valley, producers and processors struggle with high solids loading in their process water and wastewater applications. Regulations and standard process procedures require high solids isolation from their process streams. Rotary screens often fail to meet regulation standards and remove the required number of solids to avoid fouling the downstream equipment. Producers and processors are finding success with automatic, self-cleaning filters that bridge the gap between this void in the process line.

Case study 1: High solids removal equals high product yield

A common example is the assumption that centrifuges will solve high solids loading problems. However, producers must also consider the total amount of product lost versus the yield and flavor profile changes.

One pomegranate grower/producer in Stockton, California, experienced this problem, decided to address it with an automatic filter and was ultimately able to remove the centrifuge from its filtration process. With the centrifuge, for every 3,000-gallon batch of pomegranate juice, the producer experienced a loss of 400 gallons of product. Moreover, the producer had to ship product off-site for centrifugation because the $30,000 purchase price per unit was not an affordable option.

According to the owner, another issue was that the centrifugal forces applied during the process created an unwanted flavor profile change. While product quality is crucial to meet customer satisfaction, no matter what the juice is, pomegranates are especially demanding because of the amount of pulp involved.

The producer purchased a 15-micron automatic, self-cleaning filter skid as part of its on-site processing system. The results were dramatic. Influent process fluid entered the automatic, self-cleaning filter at 8 percent solids, reducing the effluent stream down to 1 percent solids. Total product lost per 3,000-gallon batch was reduced to 85 gallons, or 1.7 percent – a significant reduction from 400 gallons.

Another benefit was increased production. Whereas the off-site centrifugal system processed 6,000 gallons during a two-day period, the new automatic, self-cleaning filter system processed juice on-site and increased production to 40,000 gallons during the same period.

Overall, the new system represented a 33 percent reduction in filtration costs, a 100 percent decrease in trucking costs and a 78 percent reduction in product loss. Having an on-site solution gives the producer control and oversight of the entire process, from farm to bottle.

Case study 2: Regulatory compliance with TSS and BOD reduction

Process issues are not the only problems haunting the industrial market. Managing wastewater with high solids is an ongoing challenge, and with tighter regulatory standards, solids isolation is a crucial step in this environment. Given increasing water rates and regulatory pressures, food and beverage operators are turning to water reuse and recycling initiatives. This is a challenge because wastewater is generated in all areas of food processing, including dehydrating, washing, peeling, blanching, sorting and sanitizing.

A California raisin producer dehydrates and packages its product, creating a high solids waste stream that cannot be reused. The company used a treatment system for its wastewater sump, which included a shaker bed and drum screen, before discharge to a local treatment plant.

This process worked until regulatory standards required cleaner discharge water. The wastewater discharge from the raisin producer exceeded the TSS and BOD limits of the local treatment plant. Publicly owned treatment facilities are can typically receive food-processing wastewater with BOD values no greater than 250 to 300 milligrams per liter, well below the company’s regular output.

The treatment facility operators contacted the raisin producer and requested lower TSS and BOD. The company tried solutions ranging from filter screens to a reverse osmosis (RO) system. Traditional automatic filters clogged, and microfiltration, ultrafiltration and RO systems were too expensive to operate.

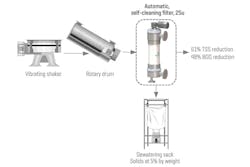

Marginal improvements came with the implementation of a food processing shaker bed with a 5-millimeter mesh to remove the coarse solids, followed by a rotary drum screen with a 250-micron mesh to remove finer solids. However, the drum screen failed to provide the necessary TSS reduction.

In summer 2016, a technology provider recommended installing a 25-micron, automatic, self-cleaning filter to follow the drum screen. Combined with a simple dewatering sack, the filter concentrated solids up to 5 percent by weight and produced dewatered solids that could be used for fertilizer or sent to a landfill. In the first month of the filter’s operation, TSS levels dropped by 61 percent and BOD by 48 percent from the previous five months of operation (see Figure 1).

Conclusion

Some specialized automatic, self-cleaning filters allow filtration process systems to bridge the gap between primary filters and final filtration. Solids concentration by dewatering allows for easy disposal, transportation, and high solids filtration.

By eliminating problematic filtration methods, this cost-effective solution gives users the confidence that their process flow will not be inundated with high solids, which no longer have to be transported through the entire system. In addition, by eliminating this problem with a necessary filtration step, high solids automatic filters allow for immediate removal preventing downstream flow reductions and unnecessary equipment procurement.

Dante Fernandez is an applications engineer for Spiral Water Technologies. He may be reached at [email protected].