Convective Thermal Drying System Helps WRF Save Energy

By Brian Novak

In 2001, the city of Corona, Calif., built a state-of-the-art biosolids drying facility that uses 500ºF of waste heat from its then-new combined-cycle cogeneration plant to pre-heat the biosolids dryer's combustion air and to supply the low-grade heat required to promote biological growth in the water reclamation facility's digesters. Waste heat from the power plant is also beneficially used to produce Class A biosolids.

Locating Corona's drying facility and electric generator system adjacent to one another reduced construction expenses and is saving operational costs.

"Combining the facilities not only saved energy but also costs," said Tom Moody, operations manager. "It reduced construction costs, and operating costs are reasonable as some of the same personnel operate both systems."

The facility realized further savings when it selected a Sernagiotto directly heated biosolids dryer from Siemens Water Technologies. The convective thermal dryer processes 110 wet tons per day of municipal biosolids. The dryer's burner is fueled by natural gas and digester gas. Using digester gas, when possible, saves the city an extra 2.3 million btus per hour of natural gas.

The biosolids dryer produces an end-product that complies with the US EPA 40 CFR Part 503 Rule for heat-dried Class A biosolids. The tested heat value of the dried product is similar to a low-grade coal – around 6,500 btus per pound of product.

The Sernagiotto dryer has also reduced the normal wet cake handling to 14% of the former production volume. This has saved the city money in hauling costs but also the worry of land application limitations, both associated with the Class B biosolids that Corona produced. And the dryer has helped prevent odors that could otherwise have been a major problem because of the plant's location within city limits.

All of the biosolids, Class A or B, are sent to a facility where they are composted with biosolids from other agencies. Corona is currently working on arrangements that will allow them to participate in the beneficial reuse of the Class A biosolids produced by the dryer. These arrangements for "direct partnerships" include compost operations and cement industry alternative fuels operations in the Southern California area.

Additionally, the dryer allows Corona to recover a significant amount of water from the biosolids during processing, with the added benefit of recycling that water for use toward the recycled water system within the city.

Convective Thermal Dryer

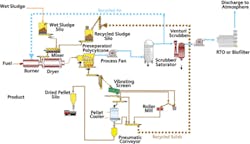

The Sernagiotto convective thermal dryer is a complete direct biosolids drying system that produces up to a 95% dry pelletized product. Corona's system, which operates 24/6, includes five main groups of equipment: mixing, drying, air/solids separation, air treatment, and solids classification.

Corona's system includes five main groups of equipment: mixing, drying, air/solids separation, air treatment, and solids classification.

Wet and recycled dry sludge are first mixed to produce a 1 - 4 mm sphere that has a solid dry core surrounded by a thin wet film of sludge. The mixed product that is formed has a total solids concentration of about 64 – 66% and a bulk density of about 55 lb/cu. ft.

Next, natural gas or a combination of natural and digester gas is fed to a furnace that generates hot air. The hot air is blown into the drum dryer where the semi-dry mixed sludge product is introduced. The mixture is then pneumatically conveyed and dried through a rotary drum dryer constructed of three interconnected concentric cylinders. In addition to reducing the dryer footprint, this triple-pass drum dryer design provides further efficiencies in the drying process by consistently maintaining the desired temperature for drying without creating any "cool zones" common to single-pass dryers. Water evaporated in the drying process is contained in the now-saturated air while the mixed sludge has essentially been converted to a 90 – 95% dry sludge product.

The saturated air and dry product are pneumatically conveyed to a pre-separator to separate out the gross solids via gravity. Afterwards, the solids move on to a polycyclone that removes dust and fines from the process air stream.

The air continues to a venturi scrubber for additional dust removal, where treated plant effluent is injected to completely cover the air stream. A combined wet scrubber and saturator then cools and condenses the moisture out of the air. This process air stream is further dewatered by a media-packed demister before approximately 85% of the dry air is directed back to the burner and used as process air. The remaining 15% is routed to a centrifugal separator that removes any additional moisture. The clean dry air then passes through the regenerative thermal oxidizer for VOC destruction prior to being discharged through a stack into the atmosphere.

The convective thermal dryer produces up to a 95% dry pelletized product exceeding EPA 40 CFR Part 503 Class A requirements.

A vibrating screen is used to classify solids into fine, medium, and large size pellets. A trash screen is also incorporated to remove very large inorganic products, which are conveyed to a bin for disposal. The large pellets are crushed and conveyed along with the fines to the recycle product silo. The medium size (1 - 4 mm), or final product, pellets are cooled from 158°F to 90°F in a pellet cooler. They are then pneumatically conveyed to a final product storage silo, which can house 3.75 days of dried material.

Operations and Maintenance

After years of continuous operations, the facility is meeting its designed performance. Special attention was paid to the abrasive nature of the material during the design phase to ensure the appropriate metal alloys and equipment were used to extend equipment life. Additionally, Corona's operating staff, coupled with intrinsic computer-controlled automation specifically designed for plant requirements, has helped the drying system run efficiently.

Facility maintenance has been in constant and proactive transition from reactive repairs to predictive maintenance, with production time versus downtime improving dramatically. Exchanging beneficial byproducts and sharing plant personnel have helped the plants reduce costs and operate more efficiently.

About the Author:

Brian Novak is a senior applications engineer for thermal drying technology at Siemens Water Technologies. He is located in Georgetown, MA, and can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles