Mixed Flow Exhaust Fans Help Combat Wastewater Odors

by Charlie Gans and Greg Kimmer

Modern mixed-flow exhaust fans can be used alone or in combination with scrubber systems to provide effective control if not elimination of odors from wastewater treatment plants and lift stations, and without adding unnecessary noise to the neighborhood.

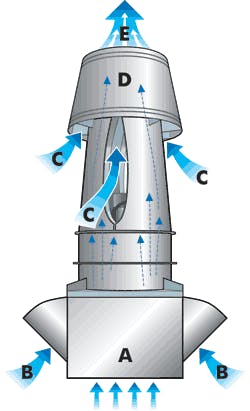

The theory of operation behind a mixed-flow impeller system is similar to fanning the air in a room to dissipate an objectionable odor - fresh air is mixed with the wastewater process exhaust gases until a suitable concentration (in parts per million) is reached and the odor is no longer perceptible or objectionable. The mixed-flow impeller fan draws wastewater treatment exhaust gas into a ductwork system, forcing it to the highest point of the facility’s roof. At the roof, the fan pulls in fresh air to mix with the exhaust gas and dilute the concentration of odor-causing gases.

Mixed-flow impeller fans can draw in almost twice the amount of fresh air as exhaust air through base-mounted bypass dampers. This mixture of air and exhaust already has a much lower concentration of odor-causing contaminants. But this is only part of the exhaust-gas-diluting process. More fresh air is entrained into the airflow when the exhaust/air mixture is ejected from the fan and the rooftop stack at high velocity.

The diluted gas/air mixture is accelerated through a specially designed nozzle/windband before it is discharged into the atmosphere. The windband creates a protective envelope around the discharged exhaust/air mixture and keeps the surrounding air stationary to improve entrainment. This acceleration essentially creates a jet stream or plume shooting upward from the roof at an exit velocity of better than 6300 feet/minute. This exit velocity can send an exhaust plume 120 feet high into a 10 mile/hour crosswind.

Wind tunnel studies have shown that additional air is entrained into the plume through aspiration when the diluted airstream is projected upward at velocities of at least 3000 feet/minute, which is the minimum velocity specified by the ANSI Z9.5 standard for clearing chemical contaminants in laboratory workstation ventilation systems, for example. The 6300 feet/minute exhaust gas exit velocity can be achieved with a mixed-flow impeller fan moving a combination of exhaust gas and ambient air at 80,000 cubic feet per minute (CFM).

The high-velocity discharge of exhaust gas and air and aspiration effects keep the odor-laden exhaust gas from being re-entrained into the air-intake systems of surrounding buildings, and through their doors or windows.

The exhaust/air mixing approach can also be achieved with a centrifugal-type belt-driven exhaust fan system with an exhaust outlet through a rooftop-mounted steel stack. However, the stack must have sufficient height, generally 25 feet or more, to disperse the odiferous jet stream into the atmosphere with maximum dilution effect. In contrast, the exhaust structure for a mixed-flow impeller fan is typically only about 15 feet high. In addition, low-profile mixed-flow impeller fans do not require structural reinforcements on the roof of a facility and do not require the extra stabilizing hardware, such as spring vibration isolators and guy wires that are needed for use with centrifugal fan exhaust systems employing tall stacks.

Send For The Scrubbers

In many cases, the use of biological, carbon or chemical scrubbers may be needed in conjunction with the mixed-flow exhaust fans. The particular chemical content of the wastewater and the dilution levels can help determine what odor-control measures or combination of measures will be used. For example, contaminants such as hydrogen sulfide can be extremely noxious even in low concentrations, requiring a higher level of dilution than other hazardous (and perhaps less-perceptible) contaminants.

This approach has been used successfully in conjunction with a mixed-flow impeller fan system at the former Jacksonville Electric Authority (JEA) wastewater treatment facility. Because of the fast growth in the surrounding community, JEA’s lift stations were handling higher wastewater flows which were causing an increase in hydrogen sulfide emissions − at levels of 100 to 150 parts per million by volume (ppmv) at the wetwell vent without ventilation.

JEA, with more than 200,000 customers in Florida, installed a 400-cfm bioscrubber at one of its most odor-sensitive lift stations. The bioscrubber processed inlet hydrogen sulfide concentrations ranging from 3.9 to 27.7 ppmv with > 99% efficiency at a 10-second GRT, while delivering hydrogen sulfide concentrations as low as 0.03 ppmv at the outlet.

A combined system approach using a chemical scrubber or bioscrubber with a mixed flow exhaust fan can provide the most versatile means of treating odiferous compounds. For challenging cases such as the JEA plant, the combination approach succeeded where a single approach may have proven inadequate.

About the Authors

Charlie Gans, P.E., is the assistant general manager at Strobic Air Corp., a subsidiary of Met-Pro Corp., Harleysville, PA. Since joining the company in 1993, he has held positions as project engineer, engineering manager, director of operations and eastern regional manager. Gans maintains a Professional Engineering license in the Commonwealth of Pennsylvania. He has designed a variety of fan impellers and air moving systems, mainly for air pollution control and energy recovery applications. He may be contacted at [email protected]. Gregory C. Kimmer is a Vice President of Met-Pro Corporation and General Manager of the Duall Division of Owosso, MI. He is a graduate of Michigan State University, and has been actively involved in the air pollution and municipal odor control industries for more than 30 years.