Cover System Helps Store Biogas for On-Site Power Applications

by Thomas Mangione

Facilities across the country are touting the benefits of using biogas, a byproduct of the anaerobic digestion process, as a source of renewable energy that does not add new greenhouse gases to the atmosphere. Using this energy source is an essential part of any well-rounded program concerned with reducing operating costs, but providing safe gas storage is essential.

The greatest benefit it gained when biogas is stored for use at a premium time. This can be an issue, however, especially in facilities that are not operated 24 hours a day. As anaerobic digestion is a continuous but not steady-state process, gas is still produced after hours. Therefore, capturing and storing the gas safely, efficiently and cost-effectively is essential.

The produced gas has traditionally been used to heat the digestion process, which works best at either 95°F or 131°F. Biogas is also used to generate electricity, to run pumps and motors directly, and to dry and incinerate biosolids. Certain states require electrical utilities to purchase all co-generated electricity at the market rate. This rate fluctuates with demand, which is naturally higher during the day. As a result, wastewater treatment plants (WWTPs) store gas produced overnight to run generators during the day. Some WWTPs are meeting up to 90% of their total energy needs with biogas.

WWTPs in Pennsylvania, Illinois, and California are using biogas as an alternate means of heating digesters and producing electricity. Two other Illinois biogas users are maximizing their gas storage for sludge heating and odor control. And yet another Midwestern plant that uses biogas has created a more odor-free environment. What do all of these plants have in common? They are using the Dystor® gas holder system from Siemens Water Technologies.

Gas Storage

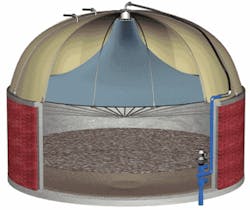

The Dystor gas holder system is designed for use on both primary and secondary digesters. Its dome-shaped, engineered membrane system maximizes storage of methane gas and sludge, while also containing odors. The manufacturer-installed system also ensures single-source responsibility.

The gas holder system includes two membranes. The outer air membrane remains inflated in a fixed position and is cable-restrained to ensure system integrity and allow operating pressures up to 16 inches water column. An inner gas membrane moves freely, as it stores or releases gas generated from the anaerobic digestion process.

An air handling system maintains a preset operating pressure between the two membranes. A fan supplies air to the air chamber when methane gas is withdrawn, and a pressure air control valve vents air to accommodate increasing gas volumes. By automatically equalizing the pressure, the air handling system keeps the outer membrane inflated while exerting a constant pressure on the stored gas. The pressure on the system can be changed by simply adding or subtracting weights to the air pressure control valve. This allows the gas holder to be retrofitted into an existing plant without having to re-ballast the entire system.

The Dystor gas holder’s operator interface allows operators to immediately determine system status at a glance. The PLC can interact with existing SCADA systems and is capable of interfacing with other digestion equipment, including co-generation systems.

Heating, Electrical Generation

Gas storage systems can pay for themselves in savings by optimizing digester gas utilization for heating and electrical generation.

Since installing a Dystor gas storage system in 2004, the Berks Montgomery Municipal Authority in eastern Pennsylvania has reduced its use of alternate fuel to heat its digesters. Before installing the cover at its Swamp Creek Publicly Owned Treatment Works, Berks Montgomery’s digester covers could not store enough gas to operate the sludge heater. The authority can now store all the digester gas it produces.

“This extra storage has allowed us to cut our fuel oil usage by 50%, or $6,000 per year,” said Jim Brady, plant superintendent of the Berks Montgomery Municipal Authority. “Our savings will continue to improve as we produce more digester gas. Our gas production depends on the amount of solids we treat.”

The Northwest Regional Water Reclamation Facility in Fox Lake, IL, also uses gas stored in its gas holder to heat the digesters.

The East Bay Municipal Utility District in Oakland, CA, an EPA Green Power Partner, uses its digester gas to produce electricity. The district runs three large generators and uses two Dystor gas holders in the 11-digester system.

The Rock River Water Reclamation District in Rockford, IL, installed a gas holder in 2001, to maximize gas storage and to generate electricity. Operators currently fill the gas holder at night and run the generators during the day when electrical demand and prices are high.

Larry McFall, plant operations manager for the Rock River District, is pleased with how the system’s electronic controls integrate into the treatment plant’s SCADA system. The controls incorporate a PLC that allows operators to monitor gas levels and other parameters. The control system also communicates directly with the generators to switch from biogas to natural gas when the gas holder is empty.

Dystor covers also allow the sludge level to be varied throughout the entire tank depth. This provides significantly greater biosolids storage variability than conventional covers. It also gives operators the flexibility to optimize sludge storage due to seasonal or other fluctuations in sludge flow.

Odor Containment

The WWTP at Crystal Lake, IL, installed a gas holder to maximize storage for sludge heating and odor control. As the plant is located in the middle of a residential area, odors are a major concern.

Steel-covered gas holders have an annular space between the cover and digester wall where odors can escape. The gas holder system, however, has membranes that seal directly to the top of the digester wall, with no annular space for emission or odor seepage.

“The Dystor system has been a good investment for us,” said Eric Lecuyer, public works director for the city of Crystal Lake. “The system allowed us to develop a good relationship with nearby neighbors, eliminate odors from the sludge digestion process, and create a more odor-free environment.”

Reduced Maintenance

The few parts of the digester that require coatings - fans and fan motors, air pressure control valves, and flame traps - all receive long-lasting shop coatings. The Dystor membrane system eliminates ongoing maintenance such as painting, roller and guide replacement.

And whereas floating covers need to be ballasted and re-ballasted, no re-ballasting is necessary with the Dystor system. As the system’s operating pressure can be set to fit into existing equipment for retrofitting an existing plant, the rest of the digestion system does not require re-ballasting.

About the Author

Thomas (Tom) Mangione is a product manager for anaerobic digestion products at Siemens Water Technologies. Located in Waukesha, WI, he joined Siemens three years ago and has worked in the industry for about 14 years. Mangione has a BS degree in Chemical Engineering from the University of Houston. He can be contacted at [email protected].

Configuration for Every Application

To best meet customers’ specific needs, Dystor gas holder systems are available in three configurations: free-membrane cover, high gas take-off style and separate storage gas holder.

The free-membrane cover, which is designed for secondary digesters or anaerobic sludge storage tanks, provides the greatest volume of air chamber displacement for gas storage and sludge variation.

The high gas take-off style is ideal for primary or secondary digesters where piping or other equipment could interfere with the travel of the inner membrane. This membrane is permanently fixed at the top so that it cannot extend very far into the tank when the system is out of service and deflated. Specifically designed for active primary digesters that have the potential for foaming, the high location of the gas take-off in this configuration keeps the foam from reaching the gas piping.

Employed when only gas storage is desired, a separate storage gas holder can be mounted directly on a concrete foundation ring. It costs substantially less than a high-pressure gas storage sphere and does not require the use of high-maintenance gas compressors. Where a high-pressure sphere exists, it can be used as a low-pressure displacement gas holder between the digestion tanks and the high-pressure sphere.