by John Fransechina

• Flexible fuel cells turn wastewater into clean energy in Tulare, CA, with distributed generation providing up to 50% of regional wastewater facility's power requirements.

California's Central Valley has seen a dramatic increase in wastewater, due partly to a growth in population and partly to the existence of some of the world's largest dairy operations. Located in the heart of the region, the city of Tulare has upgraded its Regional Wastewater Treatment Facility to address this challenge, roughly doubling its capacity during the last two years.

Being waist deep in wastewater has its benefits, as Anaerobic Digester Gas (ADG) produced from the treatment process is an integral part of a plant's energy mix, traditionally providing as much as 50% of the electrical power at many facilities. For the past 30 years, this ADG has been used to power turbines or combustion engines to generate both heat and electricity.

But cleaning the water can mean polluting the air. ADG isn't inherently clean, and wastewater treatment facilities face challenges, both in keeping their ADG-burning turbines or reciprocating engines efficiently tuned and maintained, and limiting harmful emissions these combustion technologies produce. This problem has become exacerbated as states and air quality management districts tighten environmental requirements, with California leading the way in introducing tough new environmental standards. Tulare needed to improve its ADG cost savings and renewable fuel incentives while meeting tough new emissions standards. Ultra-Clean fuel cells provided the answer, operating without combustion, generating no emissions, and using ADG more efficiently than any other distributed generation power source.

Tulare installed three Direct FuelCell® (DFC®) power plants from FuelCell Energy, Inc., to provide 24/7 electricity from ADG generated by industrial waste from the area's large food and dairy processing plants. By turning waste into environmentally-friendly energy for local residents and farmers, Tulare will enjoy the benefits of a cleaner environment today, and continue to realize the advantages of cost savings and distributed power flexibility in the future.

Fuel Cell Flexibility

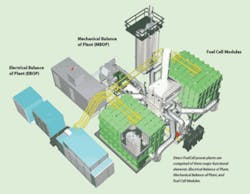

The DFC300MA is a high-temperature, high-efficiency carbonate fuel cell power plant, and is ideally configured in size for wastewater treatment plant applications. Three such units with a total capacity of 900 kW of baseload power were installed at the Tulare facility. In addition to highly efficient generation of electricity from ADG, and the ability to reduce the plant's dependence on the local power grid, the fuel cell system also made economical sense. "Our selection of the DFC power plant was based on it being less costly than alternative products, while helping us reduce harmful emissions," says Lew Nelson, Tulare's public works director.

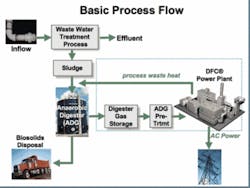

Figure 1

Fuel flexibility was also an important decision criteria for the wastewater plant. The alternative power plants can operate on a variety of fuels, including methane from biogas, waste gas from industrial processes, and natural gas. Tulare's three units use ADG, augmented with natural gas when required, to complete the hydrogen reforming process, with the natural gas provided through a standard distribution network. This ability to maximize electricity production from readily available on-site fuel is an important advantage over other types of fuel cells, which require external fuel processing to obtain a supply of hydrogen.

Wastewater In, Power Out

The Tulare plant's headworks sends 4.4 mgd of wastewater to a Bulk Volume Fermenter (BVF). The BVF separates both solid and organic matter from the wastewater, then uses anaerobic processes to convert the organic manner into digester gas, which is water-saturated and at a temperature of about 100°F. At this stage, the raw digester gas can contain as much as 2,500 parts per million by volume (PPMV) of H2S and other contaminants.

Figure 2. DFC power plants are comprised of three major functional elements.

The gas treatment system receives this gas and completes a series of steps to prepare it for use in the fuel cell. First the gas enters a series of water scrubbers and iron sponge media to remove the H2S. Next, it's compressed to 50 PSIG and moved into a heat exchanger. The heat exchanger first cools the gas to 40°F to remove most of the water, then reheats it to 65°F. This reheating raises the gas pressure dewpoint, which helps prevent any condensation as the gas is transported from the treatment system to the fuel cell. Finally, the compressed gas enters two contaminant removal vessels, where graphite media is used to remove siloxanes and other emissions of volatile organic compounds (nmVOC).

The fuel cell receives the treated digester gas and converts it into electricity exactly as it does with pipeline-supplied natural gas. Due to the high temperature at which carbonate fuel cells like the DFC300MA operate, the fuel is converted to hydrogen within the fuel cell, removing the process of external reforming and its associated costs.

Efficient Cycle of Benefits

Tulare's fuel cell power plant is the central component in the efficient operation of its wastewater treatment cycle. As a byproduct of their electrical production, the fuel cells generate heat, which is recovered and used to pre-heat sludge, optimizing the anaerobic digestion process. The result of this process is methane gas (ADG), which is then returned to fuel the plant.

Tulare can generate up to 50% of its electric power from digester gas alone, about twice the electric power generation efficiency of a micro-turbine. Adding heat recovery to the electrical conversion efficiency results in an overall operating efficiency of over 70%. Such synergies make fuel cell power plants the most clean, cost-effective, and therefore logical choice for wastewater treatment applications.

Waste heat has obvious benefits in a wastewater treatment plant producing ADG. But as valuable as the waste heat may be, it's no match for the cost of electricity required to run the plant. Electricity produced during the cogeneration process has a value 10 times as high as the associated waste heat, a fact underscored by the recent price surge for grid-supplied electricity. Therefore, reducing electrical power purchased from the grid can save significantly more money than generating larger quantities of heat for a given application.

Cogeneration with a fuel cell, especially one using ADG, helps shift the power paradigm when considering tradeoffs between waste heat and electricity production. Traditional cogeneration installations using micro-turbines or reciprocating engines typically focused on putting their copious waste heat to good use. While this approach does make efficient use of waste heat, it also can mask lower overall efficiency of the motor-driven system when compared to a fuel cell system. For example, with an electrical power generation efficiency of about 20%, a micro-turbine would provide a 1-to-3 ratio of electricity to waste heat. A reciprocating engine operating at about 33% electrical power generation efficiency yields an electricity-to-heat ratio of 1-to-2. Generating less electricity from the system means buying more electricity from the grid, and at higher prices.

In contrast, Tulare's fuel cell system, with an overall electrical power generation efficiency of 47%, provides two units of electricity for each unit of waste heat. While still capturing the waste heat from its own operating process, it creates significantly more high-value electricity that doesn't need to be purchased from the grid. This advantage means significantly higher dollar savings, particularly during periods of peak electrical demand.

Real-World Green Solution

Because fuel cells make their energy through a noncombustible process, they produce virtually zero emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM). Regardless of whether Tulare is operating its fuel cells on digester gas, natural gas or any combination of the two fuels, the plant remains classified as an Ultra-Clean installation under California law. And staying green environmentally can mean saving green financially in a tough regulatory climate. The installation provided an immediate actual savings of $600,000 in Emission Reduction Credits for the city, and qualifies Tulare for over $4 million in incentives under California's Self-Generation Incentive Program (SGIP).

This fuel cell is certified to meet the stringent distributed generation emissions standards established by the California Air Resources Board (CARB). In addition to qualifying it as an Ultra-Clean technology, it meeting this standard also exempts the fuel cell it from air pollution control and air quality district permitting requirements, giving it preferential rate treatment by the California Public Utilities Commission (CPUC) and elimination of additional exit fees and standby charges. Thus the fuel cell system demonstrated its ability to save Tulare money, not only with its efficient operation, but also with fast-track installation and rate benefits.

Conclusion

Fuel cells keep their cool in a crisis, and unlike turbines and reciprocating engines, demonstrate virtually no power drop-off at ambient temperatures of 100°F and higher, a common occurrence during hot California summers. Rather than representing an added strain on the local power grid during these increasingly common incidents, fuel cell power plants like the one at Tulare continue to operate efficiently, reducing demand from the grid and contributing to the overall amount of available electricity.

The local dairy industry can appreciate these benefits also, as more available power means more hours to produce milk, butter and ice cream. By cleaning the water and air, keeping the wastewater treatment system functioning under severe conditions, and helping to ensure reliable electricity for their commercial neighbors, Tulare's fuel cells continue to demonstrate their value as a friendly, flexible power source. If it's true that good milk comes from happy cows, then good clean power can help keep everyone – cows and people – happy and productive in California's dairyland.

About the Author: John Franceschina is vice president of business development for FuelCell Energy, based in Danbury, CT. Contact: 203-825-6000, [email protected] or www.fuelcellenergy.com