By Fred Grondhuis

p>Large-scale seawater reverse osmosis (SWRO) plant operators are increasingly converting from impulse rotary energy recovery technology to isobaric systems to reduce the total cost of produced water and maximize output. Isobaric technology can recover up to 98 percent of the energy in the brine waste stream. Energy consumption is typically the single largest cost driver of desalination, thereby making energy recovery equipment economically critical to SWRO processes.

A significant number of existing 10- to 20-year-old SWRO plants continue to use reverse running pumps as energy recovery turbines (ERTs). Once state-of-the-art systems, ERTs produce unnecessarily high operating expenses (OPEX) by today’s standards and are no longer the most efficient energy recovery solution available. As energy costs continue to increase, a system evaluation will recognize that even marginal efficiency gains will translate into significant OPEX savings.

ERD Selection

By their nature, isobaric energy recovery devices (ERDs) are highly efficient. But like all machines, ERDs are subject to system losses that degrade performance. These include mixing, leakage, over flush and differential head. Of these, mixing and leakage have the biggest impact and therefore must be minimized.

“Mixing” refers to contamination of the seawater by brine prior to the seawater entering the membranes. Because the required membrane feed pressure increases with salinity, the consequence of a high mixing rate is greater power consumption by the high-pressure feed pumps.

The mixing rate for the best available isobaric ERD technology is quite low, less than 2.5 percent by volume, which results in slightly more than 1.0 percent mixing at the membrane inlet. For a plant with a permeate flow rate of 190,000 m3/h (836,000 gpm) and a conversion factor of 45 percent, every 1.0 percent of mixing over an isobaric ERD results in an additional annual energy cost of approximately $84,000, assuming $.142/kWh.

Another important factor to consider is the leakage rate, also known as lubrication flow. Leakage refers to the direct discharge of high-pressure brine. The net effect is a reduction in the amount of high-pressure brine from which energy can be extracted. To compensate, the high-pressure feed pump must produce higher flow, thus consuming additional power.

The leakage rate of the best isobaric ERDs is approximately 0.4 percent of incoming high-pressure brine flow. Assuming the aforementioned operating parameters, every 1.0 percent of leakage over an isobaric ERD adds about $283,900 to the annual operating cost of the plant.

For the purposes of determining the total cost of ownership, energy costs must be calculated from published efficiency figures and system loss rates. It is clear that even small differences in system loss rates among alternative ERD designs can amount to a substantial increase in operating costs, particularly when carried over 25 years or more.

Other items to consider when evaluating ERDs and, specifically, those using isobaric technology include:

- Shape of the efficiency curve: A flat efficiency curve enables efficient operation under the varying flow and pressure range found in any SWRO plant. This will improve the plant’s ability to adjust output to meet daily fluctuations in demand.

- Backpressure: In most cases, the lower the backpressure an ERD needs for proper operation, the lower its risk of cavitation. Cavitation can increase maintenance costs and lower efficiency. Slow speed units typically require lower backpressure.

- Ability to pass solids: Is the device tolerant of solids or does it require special flushing procedures, costly strainer or filtration systems?

- Noise level: Does the unit produce noise below the Occupational Safety and Health Administration threshold of 85 dB? If not, noise abatement measures such as hoods or enclosures are needed.

- Life expectancy: How long will the unit last relative to the investment made? Slow-speed machines typically experience less wear (and cavitation) and, therefore, last longer than their high-speed counterparts.

- Expected maintenance costs: How much will the device cost to maintain over its life? What is the maintenance experience at other plants where these ERDs are installed? Will routine maintenance require specialized tools or shop equipment?

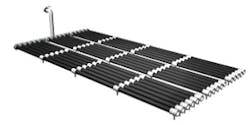

Dual Work Exchange Energy Recovery System

Based on isobaric technology, the dual work exchange energy recovery (DWEER) device can recover up to 98 percent of the energy in a brine waste stream. That energy can be used to pressurize raw water and reduce the energy input for the high-pressure feed pumps of a seawater reverse osmosis system by up to 60 percent.

DWEER™ systems are manufactured by Flowserve (www.flowserve.com).

With the dual work systems, the high-pressure pump does not have to be connected to the energy recovery device. This permits the use of fewer, but larger energy-efficient pumps. Power recovery is independent of the high-pressure pump flow rate, so there is no critical best efficiency point with the system. Because of its flat efficiency curve, the device is able to operate efficiently under the varying range of flow and pressure found in any SWRO plant without adjustment.

In a dual work system, the high-pressure pump flow rate is equal to the product water flow rate plus system losses. The high-pressure brine from the membranes is directed to a work exchanger vessel filled with seawater. The work exchanger vessel pressurizes the seawater to brine pressure.

A small recirculation pump is used to equalize the pressure of the seawater, leaving the work exchanger with that of the high-pressure pump, overcoming membrane and system losses. The seawater then joins the flow from the high-pressure pump to form the membrane feed flow.

As the end of this half-cycle nears, an actuated piston in a Lynx valve diverts the high-pressure brine to the opposite work exchanger vessel. The low-pressure seawater (from the same source feeding the high-pressure pump) then fills the spent work exchanger vessel displacing the brine to discharge, and the cycle repeats.

Flowserve offers purchasing agreements than can be tied to the efficiency and reliability of the ERD system. In the agreement, the company shares in the risk-reward of the energy recovery system’s performance by recouping the cost of its equipment and services over a five-year period. Payment is tied to the plant’s annual water production and energy savings to amortize the investment.

The program can cover maintenance of the entire energy recovery system, including pumps. Proposed services include scheduled maintenance site visits, mechanical settings, replacement of consumables, data collection and stock management. Emergency repairs, including all labor, parts, settings and start-up, are covered in the tender also.

To further ensure system reliability and plant availability, the project can include remote monitoring. Instrumentation, software and hardware powered by an intelligent technology platform can be employed to collect and analyze critical performance data. This interface enables plant operators to implement corrective action or make system adjustments as needed to maintain peak energy efficiency and maximize finished product output.

Concluding Comments

As with any capital investment, the true cost of an ERD is more than just the purchase price of the unit. The true total cost consists of the capital costs (including installation), the operating costs and the maintenance costs. Since system losses and equipment reliability can have a profound impact on operating and maintenance expenses, respectively, it is imperative to calculate the accurate total life cycle cost before making a purchasing commitment. Also, by selecting an ERD provider that will guarantee energy efficiency and plant vailability through a performancebased purchasing agreement, SWRO plant operators can upgrade to state-of-the-art ERDs with little initial expenditure, in some cases, even no initial expense.

About the Author:

Fred Grondhuis is the Flowserve Strategic Marketing Manager for the Power and Desalination industries. He holds an MBA in international marketing. He has been with Flowserve for 30 years and has held positions in sales, manufacturing, business development and marketing. He may be contacted at [email protected].