Reducing waste and costs with solid/liquid separation in zero liquid discharge processes

By Malte Junker

Dwindling global water resources coupled with growing environmental awareness has made the integration of waste reduction, process efficiency and product recovery more and more of a priority in production processes. One efficient way of addressing these challenges is zero liquid discharge (ZLD). This highly effective method is used for eliminating wastewater discharge, recycling water, and recovering valuable solids and chemicals.

ZLD – What Does It Involve?

ZLD refers to a treatment process commonly used in a range of applications. The primary goal of a ZLD process is to eliminate the liquid waste from a system; its benefits are both economic and ecological as most of the wastewater elements can be recycled or reused after the process. Because less waste accrues and no process water is wasted, installing a ZLD process can help make a plant more environmentally friendly or assist in meeting government regulations regarding waste disposal.

This explains ZLD’s popularity, which started in the 1990s and has rapidly grown in recent years. It is a straightforward way of improving the environmental credentials of industrial plants in a wide variety of sectors, from chemical production and oil and gas to power generation. This innovative method has proven to be of great value, particularly in regions where fresh water is a scarce resource. In addition to reducing a plant’s ecological footprint by eliminating wastewater discharge, ZLD also increases water reuse and allows for the recovery of valuable byproducts. This not only helps companies to meet stringent wastewater disposal regulations and water reuse guidelines but also improves their public image as essential part of their Corporate Social Responsibility (CSR) objectives.

When it comes to ZLD processes, zero waste also means higher profit, as fewer resources and products are wasted. One example is the resource water, which can be reused as wash water after clarification instead of going to waste. But product residues that would otherwise go to waste can also be reused; lithium, a material currently in massive demand, is common in mining applications. Besides the lower environmental footprint, economic goals are also met due to optimal water reuse and the recovery of valuable byproducts.

A Typical ZLD Process

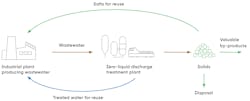

ZLD is not limited to a single process; it has many different variants. One thing they all have in common is the importance of solid/liquid separation to function successfully (see Fig. 1).

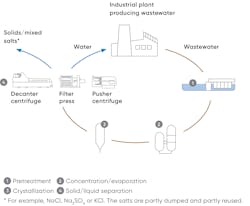

In the pretreatment step, the waste stream is conditioned, and easy-to-remove waste and chemicals are filtered or precipitated. In the second step, the waste stream is concentrated, for example by using reverse osmosis and/or evaporation. In the third step, the concentrated waste stream is fed into a crystallizer, where crystals are formed. The waste stream now consists of crystals suspended in water.

This stream is then fed into the solid/liquid separation system, which, as the final step of a ZLD process, is crucial for the efficiency of each ZLD installation. This step is where the valuable water is separated from the solids. For each milligram of solids remaining in the water and each percentage of water remaining in the solids, a price has to be paid either by the plant operator, who loses valuable material that would have otherwise been reused, or by the environment, if hazardous particles end up being deposited in the brine or valuable water is wasted. The importance of solid/liquid separation in the entire ZLD process shows that the right high-quality equipment is essential in order to keep the process running at maximum efficiency (see Fig. 2).

What to Consider When Selecting Solid/Liquid Separation Equipment

The challenges of ZLD should be at the forefront when selecting solid/liquid separation equipment. Environmental sustainability, particle size distribution, reliability and low residual moisture are all achievable with the right equipment and the right supplier.

Environmental sustainability: Look for a supplier with experience in ZLD processes, preferably in your country, to meet the stringent regulations your legislators demand. Be sure to choose tried-and-tested, economical technology to ensure smooth operation with low energy consumption.

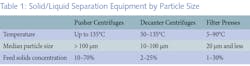

Particle size distribution: Crystal sizes and throughputs vary a lot from process to process during the ZLD solid/liquid separation stage. All particle sizes typically found in ZLD processes can be covered by the three main separation technologies: continuous filtering centrifuges (such as pusher centrifuges), decanter centrifuges, and filter presses (see Table 1).

While continuous filtering centrifuges such as pusher centrifuges are typically the most economic and efficient choice for crystals with a median diameter of over 100 μm and containing very few fine particles, decanter centrifuges generally give the best results for median particles in the range of 20 to 100 μm. In theory, decanter centrifuges also work for larger particle sizes, but they are less competitive investment-wise than filter centrifuges. For particle sizes below 20 μm, filter presses are the best solution, albeit the least common.

Reliability: As in a ZLD system, corrosion is a big issue that requires consideration of the type of filtering equipment used in addition to the processed material. Operating temperatures are typically above 80°C and can reach up to 135°C. In addition, chloride concentration is often high. To achieve reliable, uninterrupted operations, corrosion and abrasion must be kept to a minimum. In order to tackle these challenges and preserve the solid/liquid separation equipment, it should be made from well-proven, high-grade alloys such as duplex and super-duplex stainless steels or more specialized materials. This prevents corrosion and ensures uninterrupted operation. Various wear protection system can be chosen to enhance availability. The best choice often depends on the process chemistry.

In addition, enhancing tests should always be conducted in advance as lab-scale and pilot-scale testing performed by experienced specialists can give detailed advice and help you to find the best technology fit for the reliable, long-lasting runtime of your ZLD process equipment.

To ensure a long lifespan, make sure that the equipment provider has service technicians in your area and is able to provide service and spare parts in a reasonable timeframe.

Residual moisture: Achieving the lowest possible individual moisture content brings economic advantages by reducing total disposal costs. Be sure to let your chosen supplier perform tests or show you results beforehand so you get a realistic view of what you can save on disposal costs.

Case Study: Delivering ZLD Performance

A new power plant has been running in Baotou, China, since mid-2018. The plant’s overall goal was to generate power with minimum environmental impact and maximum operating efficiency. The plant deploys a ZLD process for its salt-slurry dewatering. The ZLD process cleans the exhaust gas before sending it to a crystallizer. Afterwards, an ANDRITZ A4 decanter centrifuge is used to dewater and recover the salt from the brine.

The main separation challenge involved the high process temperatures required by the crystallizing technology. The special ANDRITZ design is able to cope with the scorching temperatures while ensuring the solids emerge as dry as possible, with salt moisture not exceeding 10 percent. Apart from being extremely operator-friendly, the closed design and Human-Machine Interface (HMI) has made the equipment practically maintenance-free while increasing production efficiency to up to 20 tons of dried salt per day. IWW

About the Author: Dr. Malte Junker attended the University of Stuttgart, graduating with a degree in process engineering in 2009 before completing his Ph.D. in mechanical separation technology in 2013. He joined ANDRITZ in 2014 as a product manager for centrifuges.