By Steven C. Rohrer

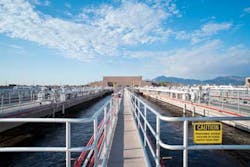

In the more than half a century since the 91st Avenue Wastewater Treatment Plant was constructed near the Salt River outside of Phoenix, it has grown and evolved to meet the changing needs of the burgeoning communities it serves - a far cry from the original plant built in the 1950s and handling 5 million gallons of sewage a day. Today, after its latest expansion, the plant can treat over 230 mgd, providing environmentally sound wastewater disposal and protecting the public health for more than two million customers.

Perhaps as significant, this "showcase" plant transforms wastewater from a liability into a valuable water resource for recycle and reuse - a critical element for water resource planning in the arid Southwest. Highly treated wastewater effluent is reused as cooling water for a nuclear power plant, as agricultural irrigation water, and to sustain an innovative constructed wetlands project, with possible future application to recharge the area's declining groundwater aquifer.

Growing and Changing

The 91st Avenue WWTP consists of six activated sludge sub-plants operating in parallel to treat municipal and industrial wastewaters from five cities - Glendale, Mesa, Phoenix, Scottsdale and Tempe - all members of the Sub-Regional Operating Group (SROG) formed in 1979 to co-own and operate the plant.

Numerous improvements to the plant were completed over the years. Five projects - plants 1A, 1B, 2A, 2B and 3A - were constructed from 1962 to 2001. Malcolm Pirnie, the Water Division of Arcadis, was the design engineer for the Plant 3B expansion, as well for the Nitrification-Denitrification (NdeN) project (1995 through 1997) that converted the plant's activated sludge system from a high-rate process to the NdeN process.

With this unique NdeN biological nutrient removal (BNR) process - its first known application in a large wastewater treatment plant - air is added in the first zone through fine-bubble diffusers to achieve mixing and jump-start oxygen-demanding reactions. Other modifications and operating changes improved efficiency, saving millions of dollars in capital costs, and an additional expansion added 8 mgd of new treatment capacity at one of the five plants at a cost of about a dollar per added gallon - only a fraction of the typical cost.

The Plant 3B Upgrade and Expansion Project also expanded the plant's process air capabilities and provided odor control for the plant's preliminary treatment facilities. It was constructed concurrent with a Disinfection Improvements Project that significantly renovated and expanded the chlorine disinfection system.

Also around this time, SROG conducted two significant solids treatment projects: construction of a new solids thickening facility for centrifuge thickening of primary and waste activated sludge and the multi-phase digestion project, which converted the plant's digestion process from high-rate mesophilic digestion to a multiple-step mesophilic and thermal process to achieve Class A sludge.

Unified Concept

In 2000, via a 25-year facilities master plan, SROG outlined its vision for a unified plan concept for all future expansions at the plant. Based on the concept of process units that operate as part of integrated systems, influent flow is commingled after each major treatment system with flow from each process area disassociated from the next and able to travel to any unit. This enables plant operators to take any single process unit out of service for maintenance needs or in the event of process upset while maintaining treatment capacity, satisfying permit water quality requirements and maintaining reliable reclaimed water production. The plan also considered impact of future regulations on advanced treatment, such as membrane filtration and reverse osmosis, as well as changing customer needs.

The Unified Plant 2001 (UP01) Expansion Project, conducted from 2003 to 2008, increased the plant's capacity to 204.5 mgd, relocated primary sludge thickening to the Solids Thickening Facility and constructed a dewatering centrate treatment facility to treat the increased ammonia concentration anticipated from the Multi-Phase Digestion Process.

This project was the first in a series of planned expansion projects that will implement an expansion philosophy developed in the 25-Year Facilities Master Plan built on commonality of process and equipment to provide greater expansion flexibility and lower the operating cost of the plant. The existing plant has six sub-plants, of which four have significantly different operating requirements. Unlike this facility, the Unified Plant, with an ultimate capacity of 385 mgd at build-out, is planned as a single facility with common sizes and operating requirements for process basins and common equipment for support systems.

Collaborative Approach

The most recent of the expansions was the Unified Plant 2005 (UP05) expansion project, which increased capacity to 230 mgd when it was completed in 2010. The UP05 expansion added 25.5 mgd of capacity and a new treatment facility to the existing WWTP - a feat of extraordinary magnitude and complexity. Engineered by Pirnie/Arcadis, these two expansions created one of the nation's largest water reclamation facilities.

The project was delivered collaboratively using a "one-team focused approach" during both design and construction. The project was complicated by the need to construct new facilities without interrupting existing operations or interfering with extensive buried utilities located in the same area. To accommodate these concerns, creative project management techniques were employed, including project partnering and focused productivity workshops. New treatment processes were integrated seamlessly with no claims or change orders, saving hundreds of manhours and thousands of dollars.

Meeting Sustainability Goals

With the completion of the latest upgrade to the 91st Avenue WWTP, the city has gone a long way in its planning for a sustainable environment to meet the needs of present and future generations. Wastewater is transformed from a liability to a valuable water resource for recycle and reuse, a critical element in the Valley's portfolio of water resources. Another "waste" byproduct of wastewater treatment, biosolids (or sludge) is also transformed from a waste to a resource. Digested sludge, processed to reduce or eliminate pathogens and minimize odors, is beneficially reused for agricultural soil enhancement instead of landfilling.

The 91st Avenue WWTP is an ideal partner for the Palo Verde Nuclear Generating Station. Located about 55 miles west of Phoenix, the station is the largest nuclear generation facility in the United States, capable of generating nearly 4,000 MW of electricity. As the country's only nuclear plant not located near a large body of water, the Palo Verde station relies on highly treated wastewater from Phoenix WWTPs to provide the more than 20 billion gallons of cooling water it needs every year - a synergy that achieves the SROG's sustainability goals.

Another application for the treated wastewater is to provide water for a plant and wildlife refuge. The SROG worked with the U.S. Army Corps of Engineers to create the Tres Rios Constructed Wetlands Project, restoring eight miles of unique riparian habitat along the Salt River, downstream of the plant. At Tres Rios, effluent is purified and ultimately recharged to the groundwater, laying the groundwork for eventual zero discharge and groundwater recharge of all effluent. The project has also restored the natural habitats for threatened and endangered fish and wildlife species, reducing the potential for flood damage, and creating a community park where the valley's residents can enjoy trails and the wetlands environment.

The 91st Avenue plant also supplies reclaimed water for agricultural irrigation to the Buckeye Irrigation Company, which purchases effluent from the plant or the wetlands for diversion into agricultural canals. Through an innovative "three way exchange" program with the Salt River Project and the Roosevelt Irrigation District, the city delivers reclaimed water to farms and receives surface water in return at city water treatment plants. Other possible future groundwater recharge and habitat restoration projects are being considered for other nearby rivers which have been affected by growth in the Phoenix metropolitan area.

In all, over 60 percent of the water "reclaimed" from the WWTP is being reused for crop irrigation, industrial cooling and habitat restoration, instead of being discharged to the dry Salt River riverbed. By continuing deliveries to current effluent customers, increasing deliveries to the wetlands and implementing other regional groundwater recharge and environmental and riparian habitat projects along other nearby riverbeds, the SROG cities envision eventual reuse of all effluent - creating a true "zero discharge" water reclamation facility.

"This will effectively make the 91st Avenue WWTP the largest water reclamation facility in the country whose effluent is 100 percent reused," said Jim Coughenour, former Assistant Superintendent of Wastewater Treatment Operations for the City of Phoenix.

Creating a 'Good Neighbor' Plant

Residential development to the north and southeast of the WWTP and the close proximity of the Tres Rios Wetlands had resulted in a different "neighborhood" since plant operations began in the late 1950s. Pirnie/Arcadis tackled these challenges by incorporating much more significant foul air containment and treatment systems in a new cast-in-place structure odor control building, virtually eliminating off-site impacts from operations. Architectural and landscape design features were intended to blend the facility into its surroundings and dramatically reduce its visual impact. Finally, locating major equipment indoors assured that operating noise would not disturb surrounding neighbors.

Dust and air pollution issues typically result from projects of this size involving significant earthwork. To accommodate Maricopa County's concerns in this area, the designers implemented dust control practices to minimize dust generation from construction activities and installed track-out devices at all entrances to keep access roads clean.

The project was named "Public Works Project of the Year" in 2011 by the Arizona Chapter of the American Public Works Association, recognizing excellence in the partnership between Pirnie/ARCADIS, engineer for the project, McCarthy Building Companies, construction manager, the City of Phoenix and the SROG cities.

About the Author: Steven C. Rohrer, PE, is a Certified Principal-in-Charge at Arcadis U.S., serving the City of Phoenix and other valley clients. He has over 20 years of industry experience managing and coordinating multi-million dollar projects. His experience includes the management, design, permitting, construction administration, and field engineering of major wastewater treatment plants and water treatment, as well as odor control studies and designs and environmental remediation and restoration. His extensive experience and knowledge of the 91st Avenue WWTP, along with proactive coordination with City staff, helped to make the UP05 B expansion a success.

WaterWorld Articles Archives