A large California power generator is using membrane technologies to treat and reuse cooling tower blowdown in a ZLD (Zero Liquid Discharge) process. In drought-stricken California, this ZLD system has set a standard for water conservation on an industrial scale.

By Peter S. Cartwright

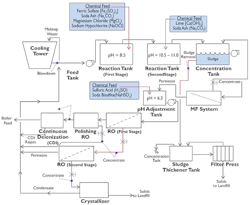

In operation since 2003, the process consists of chemical addition to the blowdown water to effect hardness and silica removal by precipitation. The precipitated solids are then continuously removed with microfiltration (MF) technology.

The MF treated water (permeate) is pH adjusted and directed to a first stage reverse osmosis (RO) unit, where a portion of its permeate is sent directly to the cooling tower as makeup water, and the remainder to a polishing RO with its permeate treated with Continuous Deionization (CDI) technology for boiler feed. Concentrate stream from the first stage RO unit is sent to a second stage RO with its permeate utilized as cooling tower makeup, and concentrate dewatered in a crystallizer. The polishing RO concentrate stream is also utilized as cooling tower makeup water.

Process description

The cooling tower is fed by clarified California Aquaduct Water. Cooling tower blowdown is pumped to a first stage reaction tank. Ferric sulfate, soda ash, magnesium chloride and sodium hypochlorite (bleach) are added; the pH in this tank is approximately 8.5, which initiates precipitation of calcium carbonate, magnesium carbonate and silica. Effluent from the first stage reaction tank overflows into a second stage reaction tank which receives lime and soda ash, raising the pH to 10.5 - 11.0, to further precipitate hardness salts and silica.

This tank overflows into a concentration tank which also receives the concentrate (reject) stream from the (MF) system. The concentration tank collects precipitated and chemically saturated solids, and the resulting sludge is fed to a sludge thickener tank.

The suspended solids slurry in the concentration tank is directed to the MF system for virtually complete removal of these solids. The MF permeate (that portion of the feed stream that passes through the membrane), flows into the pH adjustment tank where it receives sodium bisulfite to neutralize chlorine (from the bleach addition) in the tank, and hydrochloric acid to lower the pH to 6.3.

As stated earlier, the MF concentrate (that portion of the feed stream that passes across and over the membrane surface) transports suspended solids out of the MF system and back to the concentration tank. Eventually, the total solids concentration in this tank increases to about 5%, at which time, the solids are pumped to the sludge thickener tank that feeds a filter press.

Dewatered solids are hauled to a landfill and the liquid portion is directed back to the concentration tank. From the pH adjustment tank, the treated MF permeate is processed with reverse osmosis (RO) technology, and the first stage permeate stream is either returned as makeup to the cooling tower or fed to a polishing RO. Permeate from the polishing RO is directed to a Continuous Deionization system to produce boiler feedwater, and the concentrate stream becomes part of the cooling tower makeup water.

The concentrate stream from the first stage RO is fed to a second stage RO, with the permeate from this system directed back to the cooling tower as makeup water, and the concentrate stream fed to the crystallizer. Solids from this unit are delivered to a landfill, and the crystallizer condensate directed to the cooling tower as makeup.

Filtration requirements

As water evaporates, as in a cooling tower, the level of contaminants in the blowdown water increases significantly

The technologies required to remove dissolved solids (reverse osmosis, Continuous Deionization, and others), are deleteriously affected by suspended solids and slightly soluble salts that precipitate upon concentration.

Almost all water supplies, with the exception of seawater, are saturated in calcium and magnesium carbonate. Additionally, many supplies also have high concentrations of silica, another relatively insoluble contaminant, as well as sulfate salts.

Conventional lime softening is the traditional water softening process for high volume flows, and involves adding lime and soda ash. As the pH is increased from the lime addition, calcium carbonate, magnesium hydroxide and magnesium carbonate precipitate. Magnesium hydroxide also removes silica via absorption as it precipitates.

System design

The modules are divided into six skids, each containing three trains of 12 modules linked in series. The feed stream enters one end of the first module with the concentrate exiting the other end as feed for the next module. Meanwhile, the permeate from each module is collected in parallel and fed to a header where it is directed to the pH adjustment tank for further treatment by reverse osmosis.

The first stage RO removes dissolved solids with a portion of its permeate supplying the cooling tower with makeup water, and the remaining permeate flow directed to a polishing RO for additional dissolved solids removal and then further purified in a Continuous Deionization unit to produce high quality boiler feedwater.

The concentrate streams from the first stage and polishing RO units are combined and fed to a second stage RO with its permeate used as cooling tower makeup water, and its concentrate treated in a crystallizer to produce solids for landfilling.

Cleaning

Because the MF system continually dewaters the precipitated hardness and silica solids, removing the filtered water and returning the solids to the concentration tank, these solids steadily increase in this tank to 5% (wt%). At this point, the solids are drained into the sludge thickener tank ahead of the filter press.

As the solids in the concentration tank increase, the fouling inside the tubular membrane elements also increases, which reduces the permeate flow through the membrane. To minimize this, the velocity of liquid is maintained at a high flow rate (12-15 ft/sec) to ensure turbulence inside the membrane elements.

Although chlorine is added to reduce bacterial activity, the high pH environment reduces the efficacy of this disinfectant, and care must also be taken to ensure that it is completely removed prior to the RO units.

When fouling increases to a certain point, a number of procedures can be employed to restore flux, including backpulsing with air or permeate, backwashing with permeate, or interrupting the flow through the modules to allow the membranes to "relax," and fouling material to drop off the membrane surface.

Acid cleaning

When the permeate rate from the MF skid drops by approximately 15%, chemical cleaning is required. Usually, the modules are initially cleaned with a 3-5% hydrochloric acid (HCl) solution to dissolve accumulated calcium carbonate and other acid-soluble deposits.

Using a dedicated CIP (clean-in-place) system, the acid solution is pumped into the skid, and this cleaning solution is circulated through the MF modules for 15 minutes, followed by a 45 minute soak. The solution is then recirculated through the membrane system for another 45 minutes. This solution is then returned to the CIP storage tank and the modules flushed and rinsed with collected water, which is also returned to the rinse tank for reuse.

Conclusions

When acid cleaning is no longer effective in restoring the flux rate, a high pH cleaning is performed. This CIP system uses sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) in a cleaning solution containing 12-15% NaOCl at a pH of 12-13. This cleaning step is effective in reducing biofilm and other organic foulants.

The solution is circulated through the MF modules for 30 minutes, followed by a 150 minute soak and 30 minutes of recirculation. The MF system was designed with an extra skid so that one is always available for these cleaning processes, without affecting the total plant processing rate.

Each component in this system contributes to the overall success of this unique design. The chemical additions to the reaction tanks result in hardness and silica precipitation. The MF system continuously removes clarified water from the solids. This treated water is further polished with RO technology to remove salts to either generate cooling tower makeup water or to feed Continuous Deionization technology to produce boiler feedwater.

The effectiveness of MF technology is underscored by the fact that the RO units can recover a very high percentage of the treated water for complete reuse.

In addition, the RO membranes need cleaning no more frequently than every six months. The sludge resulting from hardness and silica precipitation is dewatered in a filter press and landfilled.

Crystallizer condensate is also used as cooling tower makeup. In drought-stricken California, this zero liquid discharge system has set a standard for water conservation on an industrial scale.

Peter S. Cartwright is the president of independent consultancy, PE Cartwright Consulting Co, US. For more information, email: [email protected].

More Water & WasteWater International Archives Issue Articles