Centrifugal Pump Bearings: Tips for Improving Reliability and Reducing Failure

Sept. 18, 2014

By AlLan R. Budris

As pointed out in prior columns, the second leading cause of pump breakdowns is bearing failures. This is due in part because fewer than 10 to 30 percent of all ball bearings run long enough to succumb to normal fatigue failure (L10 life: 20,000 hours for an ANSI Pump). Most bearings fail at an early age because of static overload, wear, corrosion, lubricant failure, contamination, or overheating.

Particle contamination and corrosion-related failures account for 52 percent of all of these bearing failures. Further, bearing housing seals -- more specifically the seal type -- also play a crucial role in centrifugal pump/bearing reliability. Several of my prior columns have covered the issues of bearing lubrication, particle contamination and bearing housing seals.

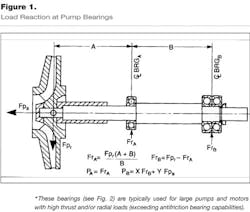

The objective of this column is to focus on the bearing types used for centrifugal pumps, their advantages, limitations, and other factors impacting bearing life. The function of the bearings in a centrifugal pump is to keep the shaft or rotor in correct alignment with the stationary parts under the action of radial and transverse (axial) loads (see Fig. 1). Bearings that give radial positioning to the rotor are known as line bearings, and those that locate the rotor axially are called thrust bearings. In most applications, the thrust bearings actually serve both as thrust and radial bearings.

All types of bearings have been used in centrifugal pumps, even magnetic bearings (see "Activated Magnetic Bearing Potential for Centrifugal Pumps," WW, March 2010). The same pump type (or model) is frequently even offered with two or more different bearing types, dictated either by varying service conditions or by the preference of the purchaser. Most pumps use either antifriction or oil film (sleeve-type) bearings, such as those listed below:

• Antifriction bearings

– Single-row, deep-groove ball bearing

– Double-row, angular contact ball bearing

– Single-row, angular contact ball bearing pair

– Cylindrical roller bearings

– Spherical roller bearings

– Taper roller bearings set

• Sleeve bearings*

• Pivoted-shoe thrust bearings*

*These bearings (see Fig. 2) are typically used for large pumps and motors with high thrust and/or radial loads (exceeding antifriction bearing capabilities).

Antifriction bearings -- and especially ball bearings -- are most commonly used in small- and medium-sized pumps because of their high speed capability and low friction. Most municipal applications use antifriction bearings.

It is essential that the balls (or rollers) in antifriction bearings be equally spaced. For this reason, a retaining cage is used between the balls and between the inner and outer races (see Fig. 3). This cage carries no load, but the contact between it and the ball produces sliding friction that generates a small amount of heat. Ball bearings are generally produced with glass fiber-reinforced polyamide, pressed metallic (of either steel or brass) or machined brass.

All cage types can be used for a large variety of pump applications. However, reliability-focused pump users will not allow the procurement and installation of bearings with polyamide cages, especially for bearing applications above 212˚F. This stance is taken because cage degradation will not appear on the most widely-used vibration data collectors and portable vibration analyzers, and also because these cages have low temperature limitations. Further, reliability-focused users avoid, or even disallow, bearings with riveted, two-piece steel cages. Rivet heads can be a weak link on some pump applications if they pop off.

The most common antifriction bearings used in centrifugal pumps are the various types of ball bearings (see Fig. 4). The most common ball bearings used on centrifugal pumps are single-row, deep-groove; double-row, deep-groove; double-row, angular contact; and universally-matchable, single-row, angular contact ball bearings. All except the double-row, self-aligning bearings are capable of carrying thrust loads as well as radial loads.

Of these, the single-row, deep-groove ball bearing is the most commonly used bearing on centrifugal pumps (except for larger size pumps). They are ideal for both radial thrust and combined loads but require careful alignment between the shaft and the housing in which the bearing is mounted. They are also sometimes used with seals built into the bearing in order to exclude dirt, retain lubricant or both. The double-row, deep-groove ball bearings -- in effect, two single-row bearings side-by-side -- have greater capacity for both radial and thrust loads.

Angular-contact ball bearings (see Fig. 5) operate on a principle that makes them ideal for heavy thrust loads. The single-row type is ideal for thrust in only one direction, whereas the double-row type, which is basically two single-row bearings placed back-to-back (or face-to-face), can carry thrust in either direction. A single-row, angular contact ball bearing can only be used singly on centrifugal pumps if the thrust is always in one direction. This type of bearing is thus primarily limited to vertical pump thrust bearing applications.

Single-row, angular contact bearing pairs are frequently matched, and the faces of the races are ground by the manufacturer, so they can be used in tandem for large, one-directional

thrust loads or back-to-back for two-directional thrust loads. Double-row, angular contact bearings, or their equivalent (a matched pair mounted back-to-back), have been found to be very satisfactory for pumps that generate a high thrust load in either direction. The life of a back-to-back bearing is about twice that of the comparable double-row bearing. Some preload is required with angular contact bearings.

Roller bearings are used less often, although the spherical roller bearing is frequently used for large shaft sizes. Since most roller bearings are suitable only for radial loads, their use on centrifugal pumps tends to be limited.

Now let's look at specific ways of reducing bearing failures and increasing bearing life:

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].